Choosing the right fabrics for screen print shirts is crucial for achieving the best results. The choice of fabrics affects screen printing, ink absorption, print clarity, and longevity. Whether you’re creating custom apparel, hoodies, or polos, understanding fabric properties is key to successful shirt printing. The fabric’s interaction with ink during the screen printing process is a significant factor to consider, regardless of whether you are using design templates or creating your own designs.

At Scalable Press, we streamline your custom screen printing experience. We provide an extensive print vendor network, a single dashboard for managing orders, and modern software interfaces. With competitive pricing and no minimum orders, we offer a seamless solution for businesses of all sizes. Our services include quick quotes, free shipping, and fast turnaround times, ensuring high-quality custom t shirts, hoodies, and sweatshirts.

Applying our expertise in custom screen print shirts, we’ve created this guide to help you choose the best fabrics. It explores top fabric options and offers tips for achieving the best results. By the end of this blog, you’ll know how to select the right fabric for any apparel project, ensuring excellent service for your customers.

Let’s get started!

Why Fabric Choice Matters in Screen Printing

Selecting the right fabric is crucial for successful screen print shirts. The fabric influences the ink adhesion, the design’s clarity, and the print’s durability. Poor fabric choices can lead to issues like ink bleeding, fading, or a lackluster finish. To ensure your screen print shirts are of the highest quality, it’s important to consider these factors carefully.

1. Fabric Texture and Weave

The texture and weave of the fabric significantly impact the screen printing process. Fabrics with a smooth texture allow the ink to lay evenly, resulting in clear, sharp designs. Conversely, rough or uneven textures can cause ink to pool, leading to distorted prints. This affects the artwork’s appearance and the print method’s durability. Fabrics like Carhartt tees, known for their sturdy weave, often produce high-quality prints.

2. Ink Absorption

Different fabrics absorb ink at varying rates, directly affecting the final look of screen print shirts. Cotton garments, for example, are highly absorbent, allowing for vibrant colors and clear details. However, fabrics like polyester resist ink, making it more challenging for printers to achieve a smooth finish. Choosing the suitable fabric ensures that your logo or artwork looks its best.

3. Durability of the Print

The longevity of screen print shirts largely depends on the fabric’s ability to hold up over time. Fabrics prone to shrinking or stretching can distort the printed design, diminishing its appearance. Selecting durable fabrics ensures that the print remains intact through multiple washes and wears, maintaining the high quality of your custom shirts.

4. Compatibility with Print Method

Some fabrics work better with specific print methods. For instance, cotton tees are ideal for traditional screen printing, while synthetic fabrics might be more suitable for heat transfers. Understanding the fabric’s compatibility with the chosen print method ensures a successful print job. The right fabric choice supports the customer service team in delivering consistent results and meeting the customer’s expectations.

5. Fabric Preparation and Handling

Proper preparation and handling of fabric play a crucial role in the success of screen print shirts. Pre-washing garments can help eliminate any residues affecting ink adhesion, ensuring a smooth printing process. Also, handling the fabric carefully during printing prevents contamination and preserves the fabric’s integrity. Proper preparation also reduces the chances of shrinkage or stretching after printing, which can distort the final design.

Top 5 Fabrics to Screen Print Shirts

When creating high-quality screen print shirts, choosing the suitable fabric is crucial. The fabric you select affects the print’s appearance, durability, and comfort. Below are the top five fabrics that consistently deliver excellent results in screen printing, ensuring vibrant designs and long-lasting wear.

1. Cotton

Cotton is the most popular screen printing fabric choice, renowned for its versatility and comfort. Its natural fibers allow excellent ink absorption, producing vibrant and long-lasting prints. Cotton is durable and provides a soft, breathable texture that is highly preferred in apparel.

Different types of cotton enhance its suitability for screen printing:

- Ringspun Cotton: Known for its smooth texture and strength, ringspun cotton is softer than regular cotton, making it ideal for high-quality prints.

- Combed Cotton: This type undergoes additional processing to remove impurities and short fibers, resulting in a finer, stronger fabric that ensures a cleaner print.

- Organic Cotton: Produced without synthetic chemicals, organic cotton is an environmentally friendly option, offering the same ink absorption qualities as traditional cotton.

Cotton’s durability and comfort make it a top choice for screen print shirts, allowing for clear, vibrant designs that stand the test of time. Due to its excellent ink absorption, durability, and comfort, cotton remains a favored fabric for screen printing. The variety of cotton types offers options for achieving high-quality prints tailored to different needs.

2. Polyester

Polyester is a synthetic fabric often chosen for its durability and resistance to shrinking and wrinkles. However, polyester presents particular challenges in the printing process. Its smooth, non-porous surface can cause issues with ink adhesion, leading to less vibrant prints than cotton. To overcome this, printers may use specialized inks for synthetic fabrics or pretreat polyester to improve ink bonding.

Despite these challenges, polyester’s durability and resistance to wear make it an attractive option for screen printing, mainly when the garment’s longevity is a priority. Polyester’s durability and resistance to shrinking make it a strong candidate for screen printing, particularly for garments requiring long-term use. Overcoming its ink adhesion challenges ensures that polyester remains a viable option for screen print shirts.

3. Cotton-Polyester Blends

Cotton-polyester blends offer the best of both worlds, combining cotton’s softness with polyester’s durability. These blends are popular in screen printing for their balanced performance and comfort. The benefits of using blends in screen printing include:

- Softness of Cotton: Provides comfort and breathability.

- Durability of Polyester: Adds strength and wrinkle resistance.

- Ease of Printing: Blends often print better than 100% polyester, with fewer adhesion issues.

Common blend ratios, such as 50/50 or 60/40, impact the printing process. A higher cotton content typically results in better ink absorption, while more polyester enhances durability and resistance to shrinking. Cotton-polyester blends offer a balanced fabric choice for screen printing, combining cotton’s comfort with polyester’s durability.

4. Tri-Blends

Tri-blend fabrics, which typically consist of cotton, polyester, and rayon, are gaining popularity in the screen printing industry due to their unique texture and softness. Each contributes to the fabric’s distinctive qualities.

- Cotton: Provides softness and breathability.

- Polyester: Adds durability and resistance to shrinking.

- Rayon: Enhances drape and adds a subtle sheen to the fabric.

The resulting lightweight fabric is soft to the touch and slightly stretched, making it comfortable to wear. The printability of tri-blends can vary, with the fabric’s smoothness sometimes posing challenges in achieving sharp, vibrant prints. However, with the proper techniques, tri-blends can yield beautiful, long-lasting designs.

5. Specialty Fabrics

Beyond the common fabrics, specialty fabrics such as bamboo, hemp, or organic cotton offer unique opportunities and challenges in screen printing. These materials are often chosen for their eco-friendly qualities or distinctive textures.

- Bamboo: Soft, sustainable, and naturally antibacterial, bamboo is an eco-friendly option that prints well but may require special inks.

- Hemp: Durable and strong, hemp offers a rustic appearance. However, due to its coarse texture, it can be challenging to print on.

- Organic Cotton: Like regular cotton grown without synthetic chemicals, organic cotton is an environmentally conscious choice supporting vibrant prints.

Proper pretreatment and selecting the right inks are essential when printing on these specialty fabrics to achieve the best results. Specialty fabrics provide diverse screen printing options with unique benefits and challenges.

Tips for Testing and Preparing Fabrics for Screen Printing

Preparing fabrics properly before screen printing is essential to achieve optimal results. Ensuring the fabric is clean, smooth, and ready to absorb ink will help create high-quality, durable screen print shirts. Here are the essential tips for testing and preparing fabrics to ensure a successful printing process.

Conducting a Fabric Test Print

Before initiating a full run of screen-printed shirts, conducting a fabric test print is essential. This initial step ensures the fabric suits the chosen design and printing method. It’s also essential to evaluate how the fabric interacts with the ink, particularly when considering complex or detailed designs. Conducting this test helps avoid costly errors and ensures the final product meets expectations.

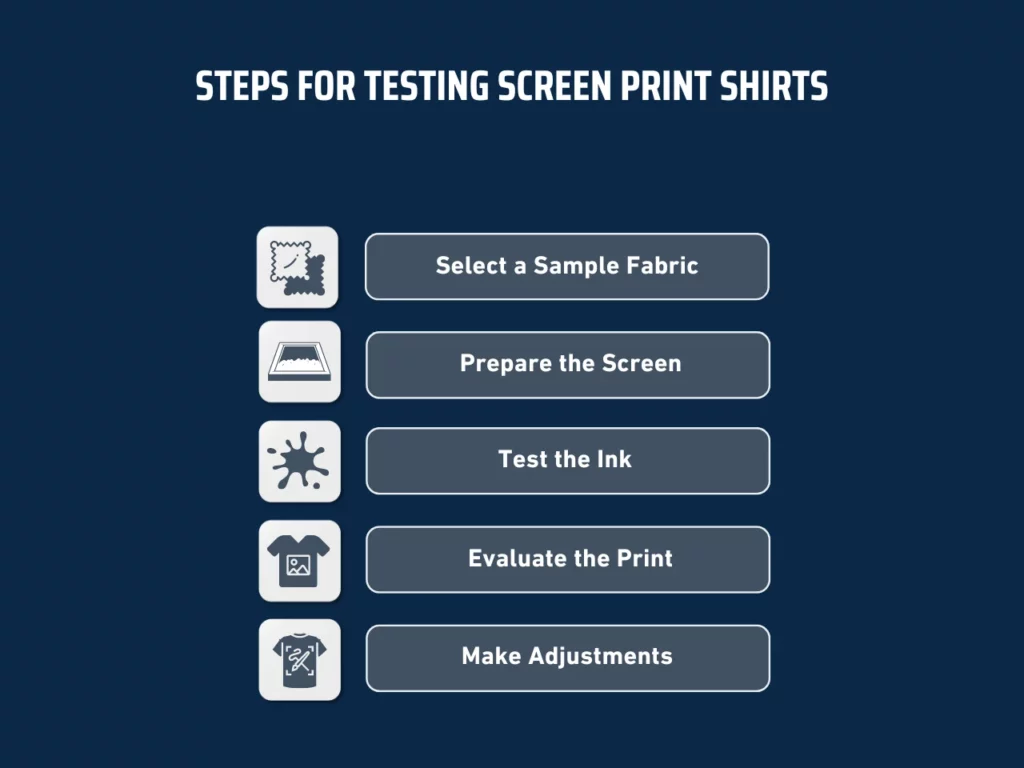

Follow these steps for testing screen print shirts on fabric before committing to a full run:

- Select a Sample Fabric: Choose a piece of fabric from the same batch intended for the final screen print shirts to maintain consistent results.

- Prepare the Screen: Set up the screen with the design intended for the final product. Ensure the design is aligned correctly and the screen is clean and debris-free.

- Test the Ink: Use the ink planned for the final run. Apply a small amount to the screen and conduct a test print. This step helps verify ink color, opacity, and adherence.

- Evaluate the Print: After the test print, inspect the fabric for ink adherence, clarity, and smoothness. This helps identify potential issues with the ink or fabric before proceeding with larger quantities.

- Make Adjustments: Based on the test print results, make necessary adjustments to the ink or screen setup to achieve the desired outcome on the final screen print shirts.

When evaluating the test print, focus on ink adhesion, clarity of the design, and durability. The ink should adhere well without bleeding, and the design should be sharp and consistent across the fabric. Furthermore, durability is a key factor as it indicates how well the print will hold up over time, especially after washing.

Pre-Washing Fabrics

Pre-washing fabrics offer significant benefits before starting the screen printing process. It helps prevent shrinkage and ensures the fabric is clean, which improves ink adhesion. Skipping this step may result in distorted designs or uneven prints, particularly on cotton or other shrink-prone materials.

To properly prepare fabrics before printing, follow these tips:

- Use a Gentle Cycle: Wash fabrics gently to avoid damaging the fibers and maintain the fabric’s integrity while removing impurities.

- Avoid Fabric Softeners: Skip fabric softeners as they can leave residues that interfere with ink adhesion, ensuring a clean surface.

- Dry Thoroughly: Ensure fabrics are completely dry before printing. Damp fabrics can cause ink to smear or not adhere properly.

- Iron if Necessary: Iron fabrics remove wrinkles, ensuring a smooth printing surface.

- Store Appropriately: After pre-washing, store fabrics in a clean, dry environment to prevent contamination before printing.

Pre-washing fabrics ensure that screen-printed shirts maintain shape and display vibrant, long-lasting designs. Proper preparation sets the stage for high-quality results, making it an essential part of screen printing.

Handling and Storing Fabrics

Proper handling and storage of fabrics are crucial to maintaining their quality before printing. Mishandling can introduce contaminants, leading to poor ink adhesion or uneven prints on screen shirts.

Here are the best practices for handling and storing fabrics:

- Keep Fabrics Clean: Always handle fabrics with clean hands to avoid transferring oils or dirt that could affect the print.

- Store in a Dry Environment: Moisture can cause fabrics to mildew or degrade. To maintain their quality, store fabrics in a dry, cool place.

- Avoid Direct Sunlight: Prolonged exposure to sunlight can fade fabrics. Store fabrics away from direct sunlight to preserve their color.

- Use Proper Containers: Store fabrics in containers that protect them from dust and contaminants.

- Label and Organize: Keep fabrics organized and labeled, especially when working with different types of materials for various screen print shirts.

Maintaining cleanliness and proper storage ensures that fabrics remain in optimal condition for screen printing. Contaminants can affect ink adhesion and the overall quality of the print, making these precautions essential for producing high-quality screen print shirts.

Key Takeaway

Achieving the best results in screen-printed shirts requires careful consideration of fabric choices. Each fabric type, whether cotton, polyester, or blends, has unique qualities that influence ink absorption, print clarity, and durability. Understanding these differences will help you select the ideal fabric for your project, ensuring your designs are vibrant and long-lasting. Digital apparel printing costs or contract screen printing considerations are equally important in maintaining the quality of your products.

In addition to fabric selection, other factors like screen printing fulfillment services can impact the outcome. Reliable fulfillment services ensure that your screen print shirts are produced and delivered efficiently, meeting the expectations of both businesses and customers. Considering these aspects will help you make informed decisions that align with your project goals, from material choice to production methods.

Would you like to explore how our screen print shirts can elevate your next project? At Scalable Press, whether you’re looking for quality fabrics or dependable fulfillment, we’re here to support your business needs. Let’s ensure the success of your next screen printing venture.