Dye sublimation printing is a versatile printing method that offers unparalleled color accuracy and vibrant, long-lasting prints on various substrates. From apparel and mugs to banners and coasters, dye sublimation uses a unique chemical process where solid ink transitions directly to a gaseous state without passing through a liquid form. This ensures a permanent bond with polyester, delivering high-quality results with superior color gamut and continuous tones.

At Scalable Press, we specialize in dye sublimation printing by utilizing our advanced digital printing technology to offer businesses top-notch services. Our process utilizes high-quality sublimation printers, special transfer paper, and state-of-the-art heat press machines, ensuring precise transfers and vibrant, long-lasting prints. Our experience with advanced digital printing techniques ensures we deliver unmatched quality for every project.

Implementing our specialized skills in dye sublimation printing, we’ve crafted this comprehensive guide to explore the fundamentals of the dye sublimation process, equipment selection, and transfer printing. By the end, you’ll understand how to achieve high color accuracy with sublimation dye printing for fabric printing, transfer printing, and beyond.

Let’s dive in!

Understanding Dye Sublimation Printing

Dye sublimation printing is a powerful and versatile printing process known for producing vibrant, long-lasting images on various materials. Its unique use of sublimation ink and high heat ensures exceptional quality in every application. Let’s explore how this technology works and its key benefits.

The Basics of Dye Sublimation Technology

Dye sublimation printing is a specialized process where sublimation ink transitions directly from a solid form to a gaseous state without passing through a liquid ink phase. This transformation occurs under high heat, allowing the ink to penetrate the material and form a permanent bond, typically with polyester or other polymers.

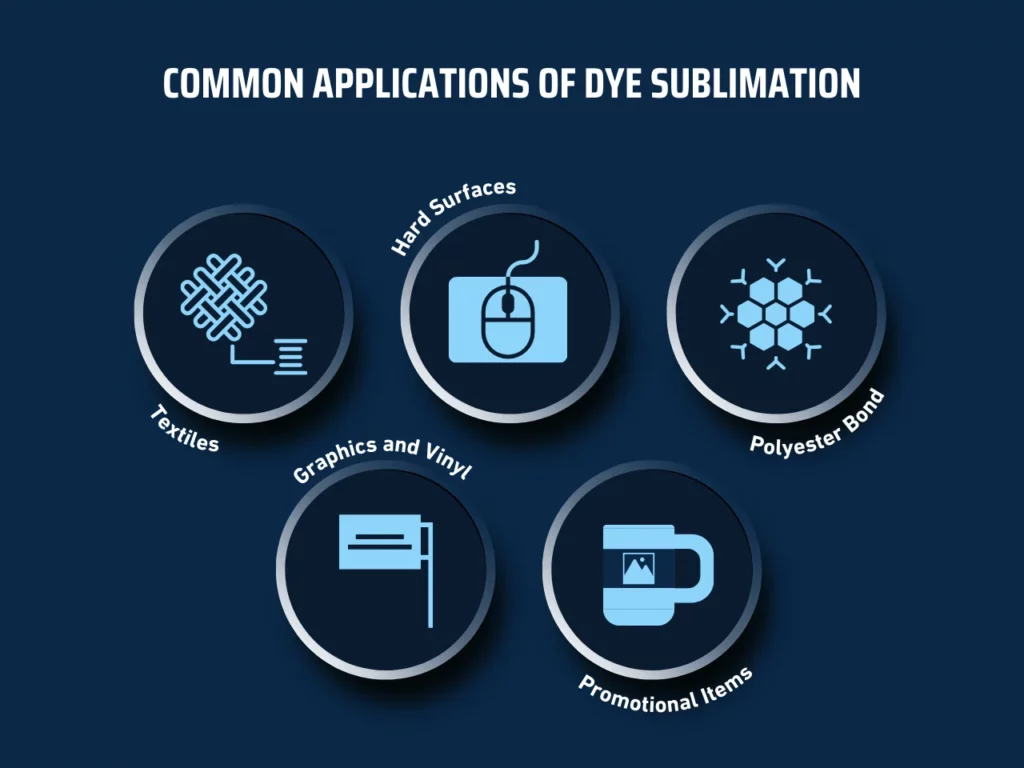

Some common applications of dye sublimation include:

- Textiles: Common in fabric printing for producing vibrant, full-color designs on t-shirts, banners, and flags.

- Hard Surfaces: Used on plaques, mouse pads, and coasters.

- Polyester Bond: Essential for ensuring high-quality prints on polyester materials.

- Graphics and Vinyl: Frequently applied in creating promotional graphics on vinyl.

- Promotional Items: Ideal for custom email marketing products like mugs and phone cases.

The Science Behind Dye Sublimation

The science behind dye sublimation revolves around carefully applying high heat and pressure to turn solid ink into gaseous ink. As the heat press raises the temperature, the ink vaporizes, penetrating the substrate’s pores and forming a permanent bond as it cools and returns to a solid state. The polyester bond created during this process ensures the durability and color vibrancy of the printed image.

Material compatibility plays a crucial role in successful transfers. The substrate must withstand high temperatures without degrading, so polyester-based materials are commonly used in dye sublimation printing. Achieving the best results also depends on carefully balancing temperature and time.

Too much heat can cause the ink to bleed, while insufficient heat can prevent the ink from fully sublimating. Additionally, the timing of the heat application is essential to avoid ghosting or incomplete transfers.

Benefits and Limitations of Dye Sublimation

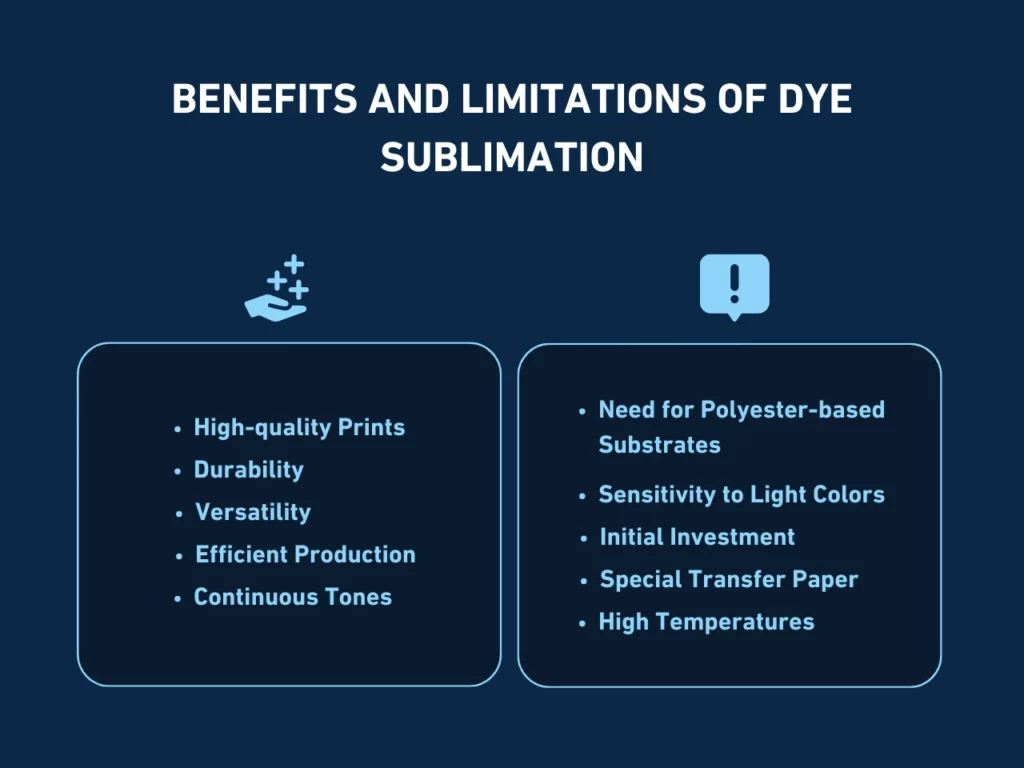

Dye sublimation printing offers numerous advantages, making it a preferred choice in various industries.

- High-Quality Prints: The dye sublimation process delivers exceptional color accuracy and detail, making it ideal for graphics and photographic images.

- Durability: The polyester bond ensures the prints resist fading, cracking, or peeling.

- Versatility: This method works on various products, from apparel to plaques and mugs.

- Efficient Production: Like DTG printers, opting for the best sublimation printers from top brands offer fast and consistent printing. This makes it suitable for large-scale production.

- Continuous Tones: Dye sublimation printing can produce smooth gradients and tones, enhancing the overall quality of the print.

However, dye sublimation also comes with some limitations to consider:

- Need for Polyester-Based Substrates: The process works best with polyester or materials with a special coating, limiting the range of compatible products.

- Sensitivity to Light Colors: Sublimation ink works better on light-colored substrates, as darker backgrounds can distort the colors.

- Initial Investment: The cost of a high-quality dye sublimation printer and heat transfer equipment can be significant.

- Special Transfer Paper: The process requires special transfer paper, which can add to production costs.

- High Temperatures: The need for high heat can limit the types of materials used and increase energy consumption.

Despite its limitations, dye sublimation printing remains a powerful tool for businesses aiming to produce high-quality, durable promotional products. Companies can effectively leverage this technology to create standout items by understanding the benefits and potential challenges.

Equipment and Supplies Needed for Dye Sublimation

Dye sublimation printing requires specific equipment and supplies to achieve high-quality results. Understanding the essential tools and materials is crucial for businesses looking to master this printing method. Here’s a guide to choosing the best options based on your needs.

Choosing the Right Dye Sublimation Printer

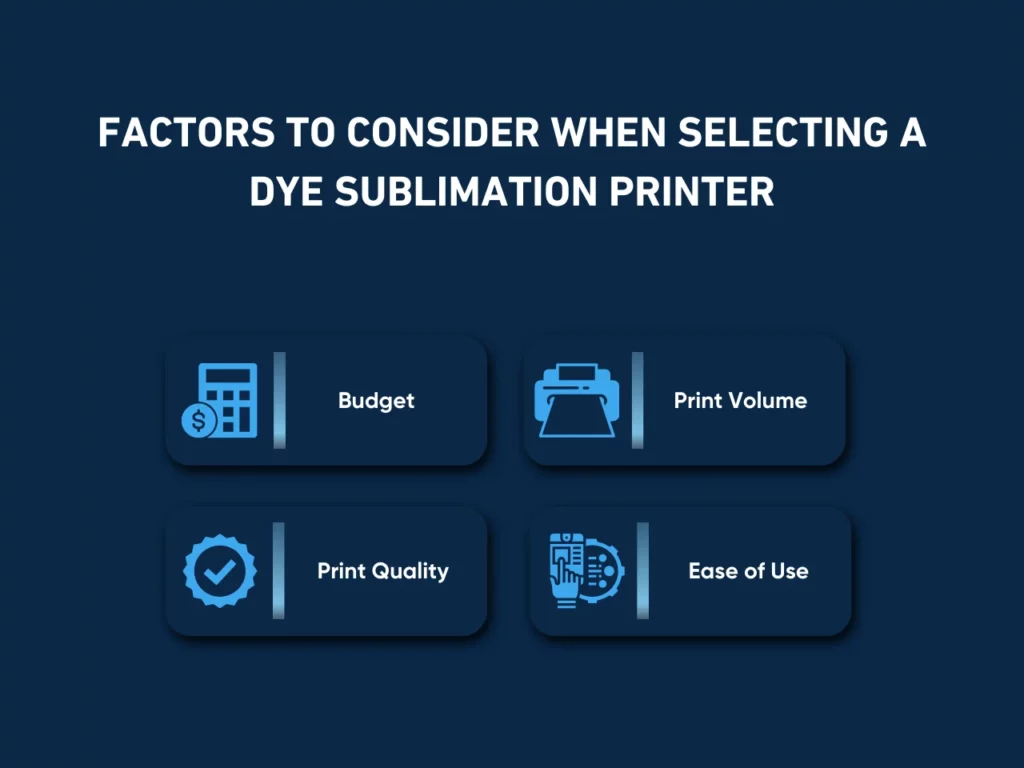

Selecting the right dye sublimation printer is the first step toward achieving excellent print quality. The printer you choose should align with your business’s requirements and the types of products you intend to create. Consider the following factors when selecting a dye sublimation printer:

- Budget: Determine how much you are willing to invest in a printer. Entry-level models are available for smaller budgets, while higher-end models offer advanced features for professional use. Balancing cost with functionality ensures you get the best value without overspending.

- Print Volume: Assess the volume of printing your business expects to handle. Invest in a printer designed for continuous use without compromising speed or quality for high-volume operations. More compact, less expensive models can meet lower-volume needs.

- Print Quality: Look for printers that offer high-resolution outputs. Consider features like print size and resolution to ensure the dye sublimation printer meets your quality standards. High-quality sublimation inks and excellent printer resolution can produce vibrant, detailed images.

- Ease of Use: Choose a printer with user-friendly controls and straightforward maintenance. Features like automatic cleaning cycles and easy-to-navigate software interfaces reduce downtime and make printing more efficient.

Investing in a high-quality printer ensures that your dye sublimation printing process delivers consistent, vibrant results that satisfy your customers and elevate your brand. The right printer enhances your production capabilities and sets the foundation for achieving the best possible outcomes in every project.

Essential Supplies: Inks, Papers, and Substrates

To achieve the best results in dye sublimation printing, it’s important to use high-quality supplies, such as:

- Sublimation Inks: These are specifically formulated for dye sublimation and are essential for producing vibrant colors and long-lasting prints. Using high-quality sublimation inks ensures that the colors transfer accurately and remain durable on the substrate.

- Substrates: The material onto which the image will be transferred is known as the substrate. Typical substrates include polyester fabrics, ceramic mugs, metal plaques, and mouse pads. Compatibility with dye sublimation is essential, as not all materials will bond effectively with the ink.

- Transfer Paper: Transfer paper plays a crucial role in dye sublimation. High-quality transfer paper effectively transfers the ink from the paper to the substrate. Selecting the right paper is critical for achieving clear, sharp images.

- Heat Transfer Vinyl: Although not always required, heat transfer vinyl can add texture or special effects to a design. It is essential when working with designs that require additional layers or colors.

- Cleaning Supplies: Keeping your equipment clean ensures consistent quality. Specialized cleaning fluids and cloths designed for sublimation printers prevent ink clogs and maintain the longevity of the equipment.

High-quality supplies ensure your sublimation dye printing projects achieve the best possible outcomes. The compatibility of inks and papers with your dye sublimation printer plays a significant role in the final print quality, making selecting these materials essential.

Heat Press Machines: Choosing the Right One

The heat press machine is a critical component in the dye sublimation printing process, responsible for transferring the ink from the transfer paper onto the substrate. Selecting the right heat press machine depends on several factors, including the type of products you are creating and your budget.

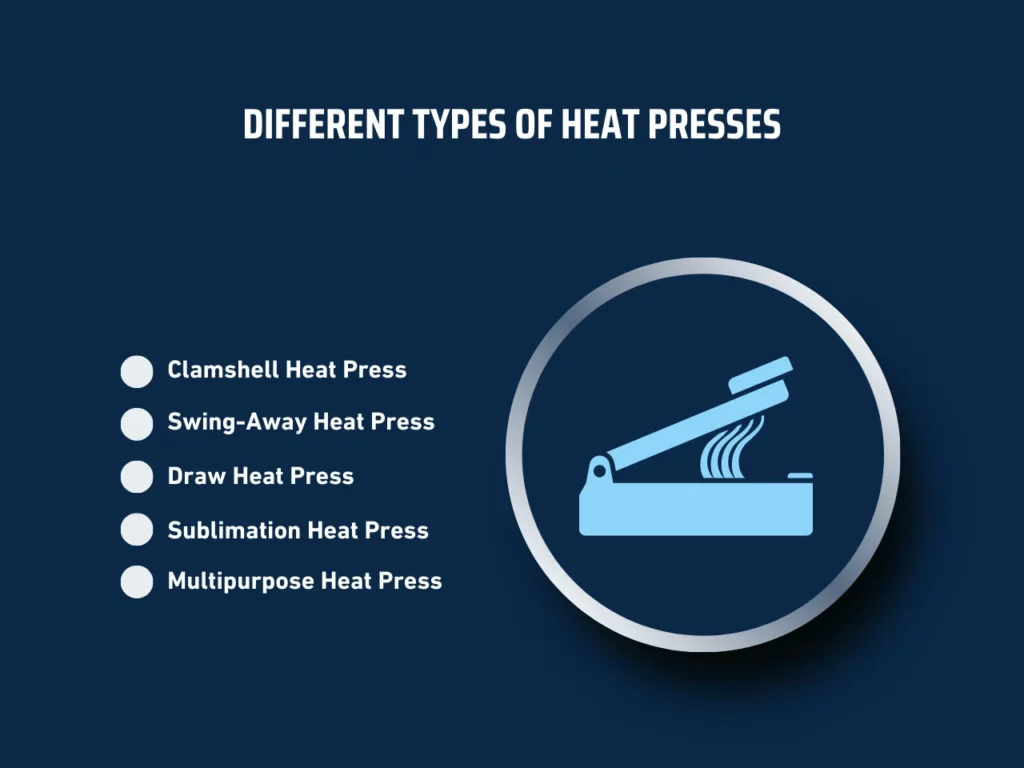

Here’s a comparison of different types of heat presses and tips for choosing the best one:

- Clamshell Heat Press: This type of heat press has a hinge that opens and closes like a clam. It is compact and suitable for small to medium-sized items. Clamshell presses are easy to use and ideal for businesses with limited space or those that primarily print on flat items.

- Swing-Away Heat Press: This machine’s top platen swings away from the bottom platen, allowing easier substrate placement. This press type is beneficial when working with thicker items or when precise placement is required, as it offers better visibility and access.

- Draw Heat Press: The lower platen can be pulled out like a drawer in a draw heat press. This design allows for the safe and easy placement of substrates, reducing the risk of burns. It is ideal for high-volume environments where speed and safety are priorities.

- Sublimation Heat Press: Explicitly designed for dye sublimation, these presses ensure even heat distribution and consistent pressure. They are essential for achieving high-quality transfers, particularly on more oversized items or when full-bleed printing is required.

- Multi-Purpose Heat Press: These machines come with attachments that allow printing on various substrates, from t-shirts to mugs and plates. Multipurpose presses are ideal for businesses that offer a wide range of dye sublimation products.

When selecting a heat press machine, consider the size of the items you will print, the space available in your workspace, and your budget. Ensuring that the machine applies consistent heat and pressure is crucial for achieving the best results in dye sublimation printing.

Beginner’s Guide to Dye Sublimation Printing

Dye sublimation printing offers an efficient method for creating vibrant, long-lasting images on various substrates. Mastering dye sublimation techniques can significantly improve your offerings, especially for promotional products. Here, we will walk you through the essential steps to achieve the best results in the sublimation printing process.

Step 1: Create Your Design

Start with creating a design suitable for dye sublimation printing. Software tools like Adobe Photoshop or Illustrator can create high-resolution graphics. Focus on color accuracy and ensure the design aligns with the dye sublimation polyester bond process. Designs should use light colors for the best sublimation printing results, as dark colors may not transfer effectively.

Step 2: Print Your Design onto Sublimation Paper

Once your design is ready, print it onto special transfer paper using a dye sublimation printer. Unlike inkjet printers that use liquid ink, dye sublimation printers require sublimation ink designed to turn into a gas when exposed to heat. Optimize the printer settings to ensure high quality and color gamut. The transfer paper plays a crucial role in the transfer process, holding the sublimation dye until it is ready to bond with the substrate.

Step 3: Transfer the Design to Your Chosen Medium

Position the printed transfer paper onto the desired substrate, such as a fabric or coaster. The alignment must be precise to avoid any shifts during the transfer process. Dye sublimation printing works best with polyester materials or substrates coated to accept the sublimation ink. This step ensures the design is ready to bond with the material through heat transfer.

Step 4: Adjust Heat Press Settings and Techniques

Set your heat press to the appropriate temperature and pressure levels, typically between 375-400°F for dye sublimation printing. The duration of pressing is also critical; most substrates require around 30-60 seconds under these high temperatures. The heat transfer vinyl should completely bond with the substrate, turning the solid ink into a gas, which permeates the substrate’s pores. Proper settings are vital for achieving vibrant and durable prints.

Step 5: Finishing Touches and Post-Processing

After the heat transfer process, allow the item to cool before handling. This cooling period ensures the gaseous ink solidifies into the substrate. Inspect the final product for any imperfections, ensuring high quality and durability. Dye sublimation printing offers long-lasting results, making it ideal for fabric printing and creating customized products with versatility and color accuracy.

Key Takeaway

Dye sublimation printing stands out as a precise method in digital apparel printing. This process ensures vibrant, long-lasting results on various materials. Understanding the core elements of the sublimation process printing, including equipment and techniques, allows businesses to deliver high-quality products that meet customer expectations.

When comparing dye sublimation printing vs direct-to-garment (DTG) printing, key considerations such as substrate compatibility and color fidelity are crucial. Dye sublimation excels in printing on polyester fabrics, making it a preferred choice for creating custom apparel. For businesses relying on a clothing fulfillment company, mastering dye sublimation offers an edge in producing consistent and durable prints.

Thinking about perfecting dye sublimation printing? At Scalable Press, we provide the resources and support you need to succeed in this competitive market. Our team is here to guide you through the process, ensuring your business stands out. Share your thoughts or questions in the comments below—we’re eager to assist you on your printing journey.