Small businesses often opt for embroidery due to its ability to enhance branding and promotional efforts. Embroidered products, such as polo shirts, showcase a professional company logo that boosts brand recognition. The question now is “How much does embroidery cost?” The cost of custom embroidery projects can vary widely, depending on the complexity of the design and the materials used.

At Scalable Press, we offer embroidery services for businesses of all sizes. With our extensive print vendor network, advanced software interfaces, and no minimum orders, we ensure that businesses can achieve their custom embroidery goals efficiently. Whether a simple logo or complex designs with high stitch counts, our team handles every detail precisely, ensuring the final product’s quick turnaround and durability.

Leveraging our industry knowledge in custom garment design, we’ve created this guide to help you understand how much does embroidery cost. You’ll learn about the factors affecting embroidery costs and budgeting tips. By the end, you’ll be well-informed about the actual costs and how to set up embroidery for your business.

So, how much does embroidery cost? Let’s find out!

How Much Does Embroidery Cost for Small Businesses?

How much does embroidery cost? Typically, it varies based on the complexity of the design, the number of items being embroidered, and the quality of materials used. The national average for embroidery services ranges between $10 and $20 per item, but prices can be higher depending on specific requirements.

Per-Item Pricing

Most embroiderers charge per-item basis, with prices depending on the type of item being embroidered. For example, custom ball caps might cost between $5 to $10 each, while more intricate items like golf shirts can range from $20 to $30. The cost increases with the complexity of the design and the number of colors used.

Here’s the cost breakdown:

- Ball Caps: $5 – $10 per item

- Golf Shirts: $20 – $30 per item

- Jackets: $25 – $50 per item

Per-item pricing allows businesses to choose options that fit their budget, with costs varying based on item type and design complexity.

Digitizing Fees

Before embroidery can begin, most designs must be digitized, converting them into a format that embroidery machines can read. Digitizing typically incurs a one-time fee, which can range from $10 to $60, depending on the complexity of the design.

Once digitized, the file can be reused for future projects, making this an essential initial investment for small businesses looking to maintain consistency in branding.

Typical digitizing costs include:

- Simple Designs: $10 – $20

- Moderate Designs: $20 – $40

- Complex Designs: $40 – $60

Digitizing fees are a one-time investment that helps maintain consistency in future embroidery projects, offering long-term savings for repeat orders.

Thread Colors and Stitch Count

The number of thread colors and the total stitch count are major factors in determining the cost of embroidery. Each additional thread color and a higher stitch count may increase the price. Small businesses often opt for designs with fewer colors to manage costs effectively. For instance, a two-color logo is more affordable than a multi-color design.

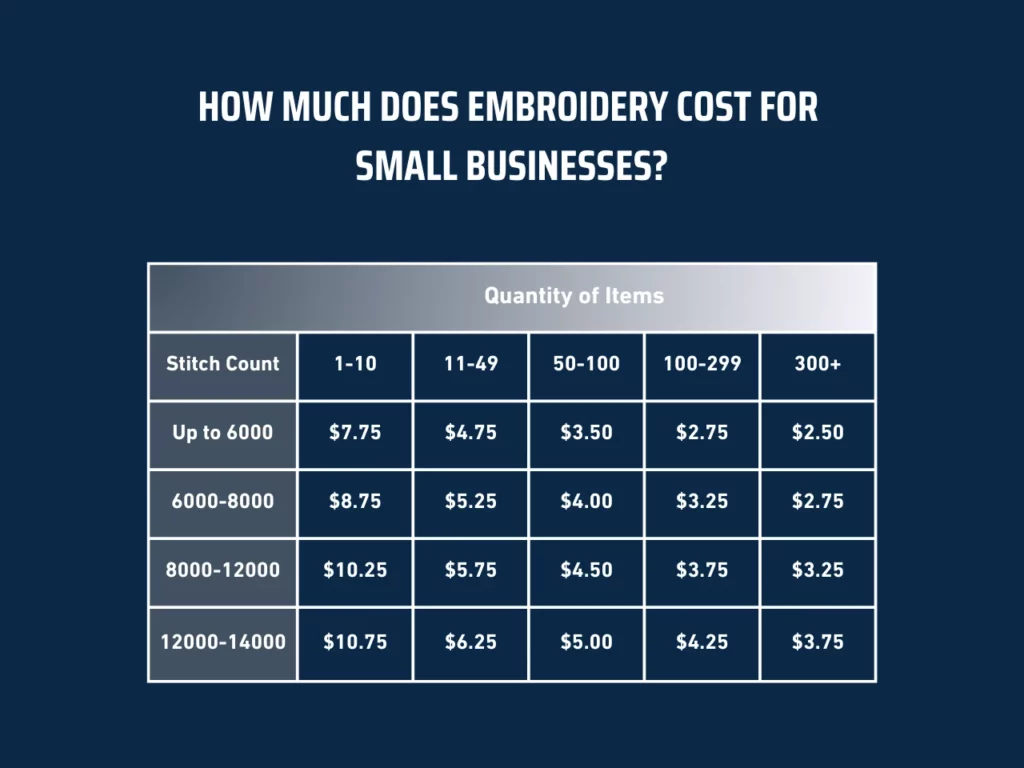

To understand stitch count pricing more clearly, here’s a breakdown that you might find on an embroidery company’s website:

This table illustrates how the cost per item decreases as the order quantity increases, providing more affordable options for bulk orders. The pricing varies depending on the stitch count, which is a key factor in determining the embroidery cost.

Volume Discounts

Ordering in bulk can lead to significant savings, as many embroiderers offer volume discounts for larger orders. For example, 100 custom-embroidered hats cost less per item than just 10. Small businesses should consider ordering in larger quantities to maximize their budget.

The following are examples of volume pricing:

- 10 Items: $10 – $15 per item

- 50 Items: $8 – $12 per item

- 100 Items: $5 – $10 per item

Taking advantage of volume discounts is a cost-effective strategy for small businesses that require large quantities of embroidered items.

Merchandise Options

Some embroidery services also offer merchandise for purchase, such as bulk shirts, hats, or other customizable items. Purchasing merchandise directly from the embroidery service can sometimes be more cost-effective, especially when bundled with embroidery services. However, some businesses prefer to supply their items, especially if they require specific brands or materials.

Factors Affecting Embroidery Costs

To understand how much embroidery costs, you must consider various factors that influence embroidery pricing. Small businesses seeking custom embroidered products must evaluate these elements to determine the total order cost. Below are key factors that affect embroidery pricing.

1. Type of Embroidery

The type of embroidery, particularly machine embroidery, is crucial in determining costs. Machine embroidery offers precision and consistency, making it popular among embroidery companies. The embroidery machine also impacts pricing, as advanced machines can handle more complex designs and thread color changes, potentially reducing the cost. However, businesses should know that more sophisticated machinery may incur higher setup fees.

2. Design Complexity and Size

The size and complexity of the design are significant cost drivers. Larger designs require more thread type and time to complete, increasing the total order cost. The number of thread colors also impacts pricing, as each color change requires machine adjustments. Embroidery companies often charge per inch of design, so intricate designs with multiple colors and detailed artwork will cost more.

3. Material and Apparel Type

The material on which the design is embroidered, such as cotton or polyester, affects the price. Some fabrics are easier to work with, reducing the embroidery pricing. Additionally, the type of apparel or accessories, whether hats, jackets, or bags, can also influence costs. Businesses providing their garments for embroidery face different pricing structures than those purchasing directly from embroidery companies.

4. Order Volume and Bulk Discounts

The volume of the order significantly impacts how much embroidery costs. Bulk orders usually lead to discounts, as the cost per item decreases with larger quantities. This is particularly true for custom embroidered items with the initial setup fee spread across more units. Businesses should consider placing larger orders for free shipping offers and reduced per-unit costs.

5. Turnaround Time and Special Requests

Rush orders and specific requirements, such as using a particular thread type or accommodating personal information requests, can increase embroidery costs. Expedited services require the embroiderer to allocate less time to each project, often with additional charges. Businesses need to plan to avoid these extra costs and stick to standard production timelines.

How to Set Up Embroidery Costs

Setting up embroidery costs involves accurately pricing your work to cover expenses and ensure profitability. This process requires careful consideration of design complexity, material costs, and labor time. Following a structured approach helps establish fair pricing that reflects the quality and effort of your embroidery projects.

Step 1: Determine the Design Complexity

The complexity of the design is a key factor in setting embroidery costs. Consider how intricate the patterns are and the level of detail required. More complex designs typically require more time and resources, increasing the overall cost.

Here’s what you need to assess to determine the design complexity:

- Stitch Count: Calculate the total number of stitches needed for the design. Higher stitch counts lead to higher costs.

- Colors and Threads: Consider the number of colors and types of threads used. Specialty threads may raise the cost.

- Design Size: Larger designs consume more thread and require more production time, affecting the cost.

Step 2: Calculate Labor and Time

Labor and time are critical factors in determining embroidery costs. The time required to set up and execute the embroidery project can vary depending on the design’s complexity and the machinery used. Accurate time tracking helps set a fair price that compensates for the work involved.

Calculate these factors when assessing labor and time:

- Setup Time: Consider the time it takes to prepare the embroidery machine, including tasks like digitizing the design if required.

- Production Time: Estimate the duration needed to complete the embroidery, factoring in any machine adjustments or rethreading that might be necessary.

- Hourly Labor Rate: Apply an hourly labor rate for the time spent on setup and production to ensure fair compensation.

Step 3: Add Overhead and Profit Margins

Overhead costs and profit margins are essential components in the final pricing of embroidery projects. Beyond the direct costs of materials and labor, it’s crucial to account for ongoing business expenses and desired profit margins. These factors ensure that your pricing is sustainable and profitable.

Consider the following when adding overhead and profit margins:

- Overhead Costs: Allocate a portion of your business overhead, such as rent, utilities, machine maintenance, and other operational expenses, to each project.

- Profit Margin: Add a profit margin to ensure your business profits from each project. This margin is typically a percentage of the total cost.

- Final Pricing: To determine the final price, combine all the costs (design complexity, materials, labor, and overhead) and add your desired profit margin.

Tips for Budgeting Embroidery Costs

Effective budgeting requires a clear embroidery cost breakdown and a strategic approach to managing embroidery expenses. This guide offers practical tips to help businesses estimate and control their embroidery pricing.

Tip 1: Understand the Embroidery Cost Breakdown

Different factors can be attributed to how the cost of embroidery differs, such as fabric, stitch complexity, and size or quantity per order. This way, you can understand costs and avoid surprises. Ask different vendors and get an embroidery cost estimate so you can have a baseline. This will allow you to compare and choose the best alternative for your needs.

Tip 2: Choose Simple Designs

Design complexity plays a significant role in embroidery pricing. Simple designs with fewer colors and minimal details are more cost-effective. When creating your logo or artwork, consider simplifying it to reduce costs. This lowers the price of embroidery and shortens production time, allowing you to receive your products faster. Simple designs can still be impactful while keeping your budget in check.

Tip 3: Order in Bulk

Ordering in bulk is a smart way to reduce average embroidery costs. Many vendors offer discounts for larger orders, which can significantly lower the embroidery cost per item. Planning and ordering in bulk can lead to substantial savings if your business requires many embroidered products. Bulk orders also provide consistency in branding, as all items will be produced together, ensuring uniformity in design and quality.

Tip 4: Plan for Long-Term Use

When budgeting for embroidery, consider the longevity of your products. Investing in higher-quality materials and durable designs can increase the lifespan of your embroidered items, reducing the need for frequent reorders.

This approach may involve a higher upfront embroidery cost but can lead to long-term savings. Planning for long-term use ensures that your initial investment pays off over time, providing value for your business in the long run.

Tip 5: Work with Reliable Vendors

Selecting the right vendor is crucial in managing your embroidery expenses. Reliable vendors offer transparent embroidery pricing and consistent quality, helping you avoid unexpected costs and delays. When choosing a vendor, look for those with a proven track record and positive reviews.

Scalable Press offers an extensive print vendor network and a single dashboard to manage orders. Their competitive pricing and modern software interfaces ensure you receive high-quality products at a reasonable cost.

Key Takeaway

Implementing budgeting strategies within a small business marketing plan can efficiently help manage embroidery expenses. Setting up a budget involves careful planning, including understanding contract embroidery pricing and choosing the right vendor. This helps businesses estimate how much does embroidery cost and plan their budgets accordingly.

When planning embroidery, it’s essential to consider how to digitize for embroidery effectively. Digitization involves converting designs into a format suitable for embroidery machines, impacting the final product’s quality and cost. Understanding this process can help businesses make informed decisions and avoid unnecessary expenses. Proper digitization is key to achieving the desired results without overspending.

Want to learn more about how much does embroidery cost for your business? At Scalable Press, we provide transparent pricing and various options to fit different budgets. Explore our product catalog to learn more about our services. Additionally, check out our guide on keeping your hat embroidery fresh and vibrant to ensure your embroidered products maintain their quality.