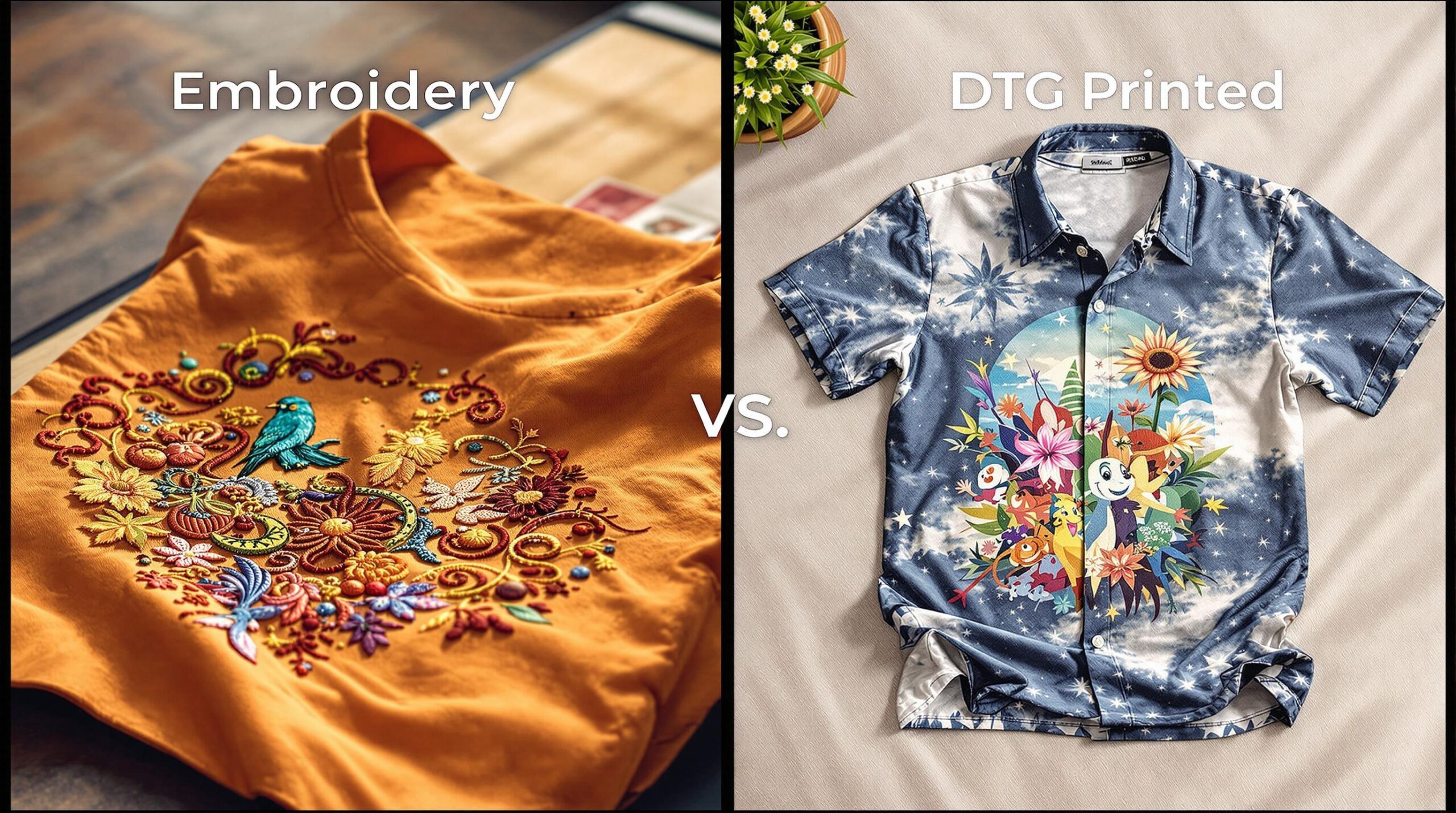

When deciding between embroidery and DTG printing for custom apparel, the choice often comes down to cost, quality, and design requirements. Here’s a quick summary:

- Embroidery: Best for durable, textured designs like logos and uniforms. Ideal for bulk orders due to scalability. Costs range from $10-$60 per item, depending on stitch count and complexity. Works well on thick fabrics like cotton or wool.

- DTG Printing: Perfect for detailed, colorful designs or photo-quality prints. Great for small orders with minimal setup. Costs start at $4.45 per item, but vary with design complexity. Works best on cotton or cotton-blend fabrics.

Quick Comparison

| Factor | Embroidery | DTG Printing |

|---|---|---|

| Durability | Very durable, lasts years | Less durable, lasts 15-40 washes |

| Design Type | Simple logos, bold text | Complex, colorful designs |

| Order Size | Cost-effective for bulk orders | Best for small or one-off orders |

| Material | Thick fabrics like cotton, wool | Cotton or cotton blends |

| Setup Cost | Higher (digitizing fees) | Minimal setup costs |

| Finish | Raised, textured | Smooth, flat |

Key takeaway: Choose embroidery for long-lasting, professional designs on durable fabrics. Opt for DTG printing for vibrant, intricate designs and quick turnaround on small orders.

Printful Review And Embroidery Vs DTG

Embroidery Overview

Embroidery is a top-tier method for creating durable, professional designs by stitching threads directly into fabric. Below, we’ll break down embroidery’s strengths and some of the challenges you might face when using this technique.

Embroidery Benefits

Embroidery offers unmatched durability paired with a textured, raised design that holds up well through repeated washing. The threads used are resistant to wear, making embroidery a go-to choice for corporate apparel and uniforms.

Here’s a quick look at how embroidery pricing typically works:

| Design Complexity | Stitch Count | Cost Range |

|---|---|---|

| Small Logo | 4,000 stitches | $4 – $10 |

| Medium Logo | 8,000 stitches | $8 – $20 |

| Large Logo | 12,000 stitches | $12 – $30 |

The cost depends on the stitch count and complexity. Most professional services charge $1–$3 per 1,000 stitches. Custom embroidered logos on shirts, including the garment, generally cost between $15 and $40 [6].

Embroidery Limitations

Despite its strengths, embroidery has some limitations:

Design Complexity

- Digitizing designs can cost $20–$60 per design [6].

- Extremely detailed designs may not translate well into embroidery.

- Large designs on lightweight fabrics can cause sagging [7].

Material Considerations

Embroidery works best on tightly woven natural fabrics like:

- Cotton

- Linen

- Silk

- Wool

“Selecting the right garment for your embroidery design is key in creating a high quality product…The high quality blank garments, constructed with heavyweight material and a high cotton count give a perfect substrate for the most complex, high stitch count embroidery designs without any pulling from the garment. The end result being a premium retail quality garment that will stand the test of time.” – Darren, Squeezed Orange [4]

For fabrics like terrycloth, using a water-soluble topping can help achieve better results [8].

DTG Printing Overview

Direct-to-garment (DTG) printing uses inkjet technology to apply designs directly onto fabric. It’s a go-to method for achieving detailed, multi-color designs and photo-quality images with impressive accuracy.

DTG Printing Benefits

DTG printing stands out for its ability to produce vivid, intricate prints with minimal setup time. This makes it a great option for small, custom orders or designs featuring complex artwork and photographic elements.

| Feature | Advantage | Best Use Case |

|---|---|---|

| Color Range | Extensive color options | Photo-quality prints |

| Setup Time | Quick preparation | Small custom orders |

| Design Detail | High-resolution output | Intricate designs |

| Ink Type | Water-based inks | Eco-friendly production |

“DTG is the ideal printing method for small and one-off jobs due to the little preparation work that’s necessary for quality printing.” – Midwest Machinery [9]

DTG printing also offers scalable production. For example, high-end machines like the Epson SureColor F2100 cost about $15,000 – making it possible to handle smaller production runs without breaking the bank [10]. However, while DTG printing has its advantages, there are some drawbacks to consider.

DTG Printing Limitations

Despite its strengths, DTG printing does come with a few challenges:

- Fabric Compatibility: Works best on 100% cotton or cotton blends. Results are less consistent on polyester and other synthetic materials, and light-colored garments deliver the best outcomes.

- Durability: Prints typically last 15-40 washes [11], which is less durable than traditional screen printing. Regular maintenance of equipment is also essential.

- Production Speed: Output is slower, averaging one shirt every two minutes [11]. This can make per-unit costs higher for small runs.

- Color Matching: Struggles with metallic shades and other specialty colors [11].

DTG printing shines when used for detailed, multi-color designs on the right materials. However, its durability, fabric limitations, and slower production speeds should be factored in when deciding if it’s the right fit for your project./banner/inline/?id=sbb-itb-bd3491f

Quality Differences

When comparing embroidery and DTG printing, the differences in texture, color output, and durability become clear. Let’s break it down.

Surface and Touch

Embroidery gives designs a raised, textured look and feel, making it a great choice for tougher fabrics like denim, fleece, or polyester. On the other hand, DTG printing creates a smooth, flat finish that blends seamlessly with the fabric, especially on cotton or cotton-blend materials.

Here’s a quick comparison:

| Characteristic | Embroidery | DTG Printing |

|---|---|---|

| Texture | Raised, threaded surface | Smooth, flat finish |

| Material Compatibility | Best for sturdy fabrics | Ideal for cotton blends |

| Touch Experience | Textured feel | Integrated with fabric |

| Design Relief | 3D effect | 2D surface |

Color Results

DTG printing delivers sharp, high-resolution colors (up to 1,200 DPI), but its water-based inks can sometimes look muted on darker fabrics [12]. Embroidery uses colored threads, which provide consistent color but may struggle with fine details like gradients or small text [2].

Product Life

When it comes to durability, embroidery stands out. Its threaded designs hold up well over years of wear and washing, resisting fading or peeling [1]. This makes it a great option for items like uniforms or corporate apparel that need to endure frequent use.

DTG prints can also last if cared for properly. Washing in cold water, using gentle detergents, and air-drying can help maintain the print’s quality. For embroidered garments, turning them inside out, using cool or warm water with mild detergent, and avoiding direct ironing over the design will keep them looking fresh.

Both methods can last a long time with proper care, but embroidery generally offers better durability without requiring as much maintenance.

Cost Breakdown

Starting Costs

When comparing embroidery and DTG printing, the initial costs can differ quite a bit. For embroidery, the main upfront expense is the digitizing fee – this is the process of converting artwork into stitch files. While the fee can seem high at first, it becomes less of a burden when the design is reused multiple times.

For example, simple logos (around 4,000 stitches) typically cost between $4 and $10 to digitize. More intricate designs, like those with 12,000 stitches or more, can cost up to $30 [5]. These initial costs play a big role in shaping the overall per-item pricing.

Item Pricing

Embroidery pricing depends heavily on the complexity of the design. On average, it costs $1–$3 per 1,000 stitches, with most custom logo embroidery ranging from $15 to $40 per shirt [6]. If you’re adding custom names or monograms, expect to pay an additional $1 to $2 per inch of lettering [6].

For more details on how pricing varies by design complexity, check out the breakdown provided in the “Embroidery Benefits” section mentioned earlier.

Cost Balance Points

To optimize costs, it’s essential to consider both the upfront digitizing fees and the per-item rates. Bulk orders are where embroidery shines, as the digitizing fee is spread across a larger number of items [6].

Key factors to evaluate include the design’s complexity, the order size, and how often the design will be reused. For businesses that stick to consistent designs, embroidery often provides better long-term value. Fully customized embroidered shirts, including the garment, typically cost $15 to $40 [6].

This breakdown can help you decide which method fits your production needs and budget best.

Method Selection Guide

Choose the method that aligns with your project’s specific needs by weighing the cost and quality factors discussed.

Best Uses for Embroidery

Embroidery works well for corporate branding, durable workwear, and high-end merchandise [1].

It’s especially suited for:

- Corporate Identity Items: Business logos and branding that benefit from a raised, textured look.

- Durable Workwear: Perfect for clothing that faces frequent washing or tough conditions.

- Premium Products: Ideal for high-end apparel where the textured finish justifies the higher cost.

- Simple, Bold Designs: Best for logos, monograms, or text without intricate details or gradients.

Best Uses for DTG

DTG printing stands out for detailed, colorful designs, quick production, and intricate artwork [1].

“DTG is fantastic for designs that are complex and colorful. It captures every detail, so your high-resolution images or intricate patterns come out looking sharp and vibrant.” – Tarang Gosalia, Optamark Graphics [13]

DTG is a great choice for:

- Photo-Realistic Images: Handles multiple colors, gradients, and fine details with precision.

- Small Batch Orders: Perfect for custom one-offs since there’s no minimum order size.

- Quick Turnaround: Ideal for projects that need to be completed in 1-3 business days [14].

- Cotton-Based Products: Works best on items made from cotton or cotton blends.

These factors form the basis of a practical decision-making guide.

Decision Checklist

| Decision Factor | Choose Embroidery When | Choose DTG When |

|---|---|---|

| Design Type | Simple logos, text-based designs | Complex artwork, photos, gradients |

| Order Volume | Bulk orders, repeated designs | Small batches, varied designs |

| Product Use | Professional uniforms, workwear | Custom gifts, promotional items |

| Material | Thick fabrics, various materials | Cotton or cotton-blend fabrics |

| Timeline | Long-term durability needed | Quick turnaround required |

| Budget | Higher upfront cost acceptable | Cost-effective small runs needed |

Carefully assess these factors to match your production needs with the right method.

For example, if you’re creating corporate uniforms for daily use, embroidery offers the durability to justify its higher upfront cost. On the other hand, if you’re producing artistic t-shirts with detailed imagery, DTG’s ability to handle complex designs and gradients makes it the better option [1].

Don’t forget to weigh each method’s environmental benefits as part of your decision-making process.

Conclusion

We’ve compared embroidery and DTG printing across durability, detail, and cost – here’s a quick breakdown.

Key Takeaways

The choice between embroidery and DTG printing depends largely on cost and quality. Embroidery stands out for its durability and polished look – perfect for professional apparel, with stitch density reaching up to 7,500 stitches per square inch[3]. On the other hand, DTG printing excels at recreating complex designs with vibrant colors, making it ideal for detailed or photorealistic artwork.

Here’s how their costs stack up:

| Cost Factor | Embroidery | DTG Printing |

|---|---|---|

| Initial Setup | Higher upfront costs due to setup | Minimal setup costs |

| Per-Item Cost | Depends on stitch count | Varies with design complexity |

| Volume Scaling | Becomes more economical with large runs | Consistent cost per item |

| Design Changes | May require additional setup work | Usually no extra setup needed |

This comparison highlights the essential factors to consider for your project.

How to Decide

Your choice should align with garment type, budget, timeline, and order size:

- Material: Embroidery works best on thicker fabrics, while DTG is better suited for 100% cotton or blends.

- Design: Embroidery is great for bold, simple logos, while DTG handles intricate, multi-color designs effectively.

DTG printing offers quicker turnaround times and steady per-item pricing, making it a good fit for businesses with fluctuating order sizes. For larger orders, especially for uniforms or corporate apparel, embroidery delivers a durable, polished finish with better cost advantages as production scales.

Leave a Reply