Technological advancements have led to the rise of DTG and sublimation printing methods known for their ability to produce high-quality t-shirt prints. Choosing between the DTG vs sublimation is essential for businesses needing promotional products. With careful consideration of quality, cost, and suitability for materials such as cotton and synthetic fabrics, these prominent printing methods have revolutionized the industry, catering to various apparel printing needs.

At Scalable Press, we use advanced DTG and sublimation printing services to deliver high-quality apparel printing. Our heat transfer methods ensure durable prints for both small runs and large orders. We offer competitive pricing, no minimum orders, and a wide range of garment printing options. Our printing process guarantees exceptional print quality, catering to complex, intricate, and vibrant color designs for various products.

Drawing from our years of experience in the t-shirt printing industry, we’ve created this guide to help you understand DTG vs sublimation. We’ll explore the overview of DTG printing and sublimation printing, their differences, and their pros and cons. By the end of this blog, you will clearly understand which printing technique suits your business needs.

Let’s jump in!

DTG Vs. Sublimation: What You Should Know

Understanding the differences between DTG vs sublimation is crucial for selecting the right printing method. Each method has distinct advantages depending on the desired outcome and material type. Exploring these differences can help determine the best choice for specific printing needs.

Overview of DTG

DTG, or Direct-to-Garment printing, is a prominent printing method in the apparel industry. Utilizing a specialized DTG printer, this method applies ink directly onto the fabric, similar to how an inkjet printer works. It allows for creating intricate designs on natural fibers like cotton fabric. DTG printing provides versatility and precision, particularly for complex designs and small production runs.

How Does DTG Printing Work?

DTG printing involves several steps to ensure high-quality prints. Follow this guide to streamline the process:

- Preparation of the Fabric: Before printing, the fabric (usually cotton) must be pre-treated to ensure ink adherence. This step involves applying a solution that helps the ink bond with the fabric, ensuring durability and vibrancy in the final product.

- Design Setup: The design is typically created on a computer and is prepared for printing. The DTG printer, which uses a print head similar to an inkjet printer, reads this digital design. This step is crucial for achieving intricate designs and ensuring the final product meets quality standards.

- Printing Process: The DTG printer applies the design directly onto the fabric using white ink and other colors. The ink is deposited onto the fabric through the print head, allowing for detailed and complex designs that are difficult to achieve with other methods like screen printing or dye sublimation.

- Heat Setting: After printing, a heat press sets the ink into the fabric. This helps solidify the design and make it permanent. Conducting this step properly ensures that the DTG prints are durable and can withstand washing and wear.

- Final Touches: Post-printing, the fabric undergoes quality checks to ensure the final product meets standards. This stage includes checking for color accuracy, design precision, and overall print quality.

DTG excels in cotton fabric and handles complex designs. Unlike sublimation, which works best with synthetic materials, DTG printing uses advanced technology like the DTG printer and delivers high-quality prints suitable for various applications, including phone cases and apparel. As the printing industry evolves, DTG caters to top-notch results for intricate designs and vibrant colors.

Overview of Sublimation

Sublimation printing is a technique where heat is used to transfer dye onto materials like polyester. This process allows for vivid and durable prints, making it a favored method in the expanding industry. Utilizing sublimation ink, this method produces high-quality images suitable for various applications such as clothing and promotional merchandise.

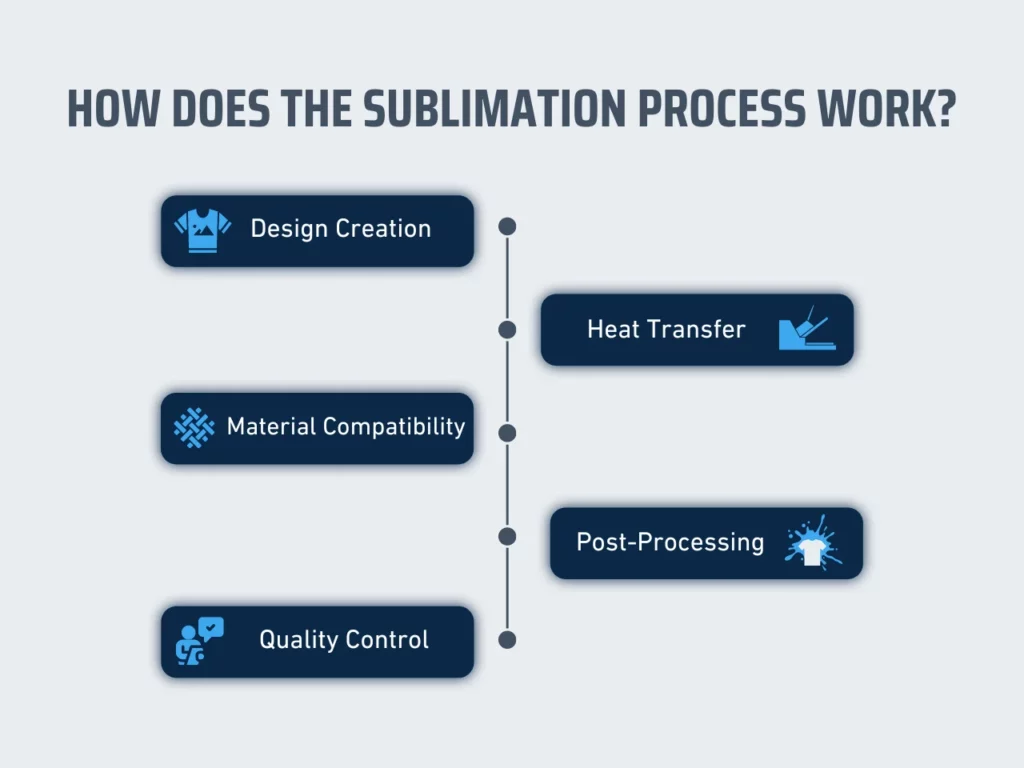

How Does the Sublimation Process Work?

The sublimation process involves several crucial factors to ensure the best results. Here are some highlights to consider:

- Design Creation: The process begins with creating a digital design, often on a computer. This design is printed in reverse (mirror-image) onto special sublimation transfer paper using sublimation ink. Mirroring the image ensures it will transfer correctly.

- Heat Transfer: Once the designs are created, place the printed transfer paper onto the material and apply high temperature and pressure using a heat press. The heat causes the sublimation ink to turn into gas without passing through a liquid state. This gas penetrates the fibers of the material, embedding the design permanently.

- Material Compatibility: Sublimation works best with polyester or polymer-coated substrates. Unlike DTF printing, which suits various materials, the sublimation process requires specific fabrics for optimal results. This limitation is a crucial factor when choosing the right printing method.

- Post-Processing: After the heat transfer, the material cools down and removes the transfer paper. The sublimation prints now feature vibrant colors and intricate details. This stage ensures that the final product meets quality standards.

- Quality Control: The final step involves checking the prints for color accuracy, clarity, and durability. This ensures the sublimation prints maintain high standards and meet customer expectations.

Sublimation is a popular and preferred method for achieving vibrant and durable prints. While DTG suits cotton fabrics, sublimation excels with polyester materials. Its ability to produce long-lasting, high-definition prints on synthetic substrates makes it a significant part of the printing industry, highlighting its importance in the global market.

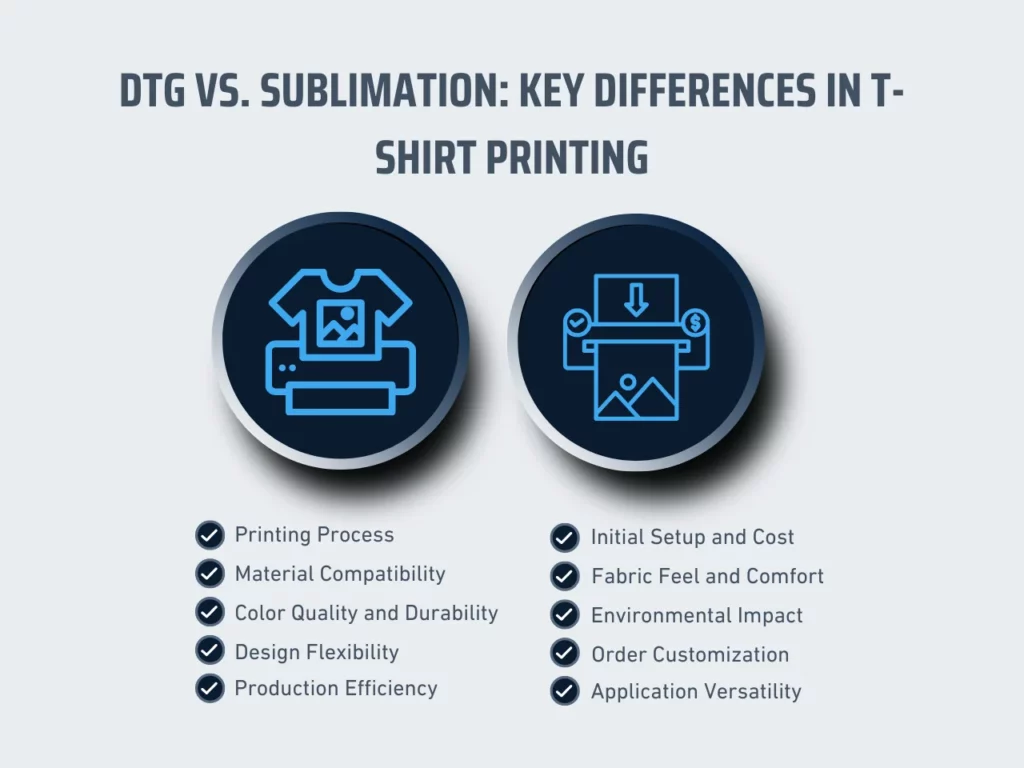

DTG vs. Sublimation: Key Differences In T-Shirt Printing

Understanding the key differences between DTG and sublimation can help businesses make informed decisions for their t-shirt printing needs. Both methods offer unique advantages and suit different applications. Here, we delve into the ten critical differences between DTG vs sublimation to guide your decision-making process.

1. Printing Process

DTG and sublimation use different printing processes. DTG uses inkjet technology to apply ink directly onto the fabric. This method resembles printing on paper but with specialized textile inks. Sublimation, however, involves a heat transfer process. Special inks turn into gas without becoming liquid, bonding with polyester fabric fibers. The DTG process offers precision, while sublimation ensures deep color integration.

2. Material Compatibility

DTG printing is a method that gives the best results on cotton fabrics. The ink adheres to natural fibers, creating bright colors and fine details. On the other hand, sublimation printing requires polyester or materials coated with polyester. The dye bonds with the synthetic fibers, making it perfect for sportswear and garments printed all over. Choosing the correct method depends on the fabric type used.

3. Color Quality and Durability

In comparing DTG vs sublimation, both printing methods offer distinct color qualities and durability. DTG provides excellent color accuracy and detail. The ink penetrates the fabric slightly, resulting in a soft feel. However, sublimation creates vivid and long-lasting colors that withstand fading and cracking. The dye is absorbed into the fabric, ensuring the design’s durability through multiple washes while keeping the colors vibrant wash after wash.

4. Design Flexibility

DTG allows for intricate, multi-color designs without additional setup costs. It suits small batches and custom orders due to its flexibility. In contrast, sublimation excels in creating bright, all-over prints. The heat transfer process enables continuous designs across the garment, offering creative freedom for bold patterns and graphics.

5. Production Efficiency

DTG printing proves efficient for small to medium-sized orders. With no screens or plates, it minimizes setup time and cost. Sublimation printing involves higher initial costs due to the need for special equipment and materials. However, it becomes more cost-effective for large-scale production, reducing per-unit costs significantly.

6. Initial Setup and Cost

DTG and sublimation have different initial setups and cost structures. DTG requires minimal setup, making it ideal for quick turnarounds and low-volume orders. The initial investment in a DTG printer can be relatively low compared to other methods. Sublimation demands a higher upfront investment due to specialized printers and heat presses. Despite the higher initial cost, sublimation offers cost benefits for large batches.

7. Fabric Feel and Comfort

DTG prints produce a soft feel on the fabric as the ink becomes part of the garment. However, it may have a slightly raised texture on the fabric surface, especially with darker colors or higher ink coverage. Meanwhile, sublimation produces a soft finish with no perceptible texture as the dye integrates with the fabric. Both DTG and sublimation methods maintain the fabric’s natural feel, ensuring comfort for the wearer.

8. Environmental Impact

DTG and sublimation offer eco-conscious choices for businesses. DTG printing uses water-based inks, which are considered more environmentally friendly. This reduces waste by eliminating the need for screens or plates. However, it can consume water during the printing process and may require pretreatment chemicals. Sublimation, on the other hand, uses less water and energy than traditional methods, as the ink is heat-transferred directly onto the fabric.

9. Order Customization

In terms of order customization, DTG and sublimation vary slightly. DTG enables easy customization for individual orders, allowing businesses to offer personalized designs without incurring extra costs. Alternatively, sublimation allows for customization but may involve higher costs for small orders due to the setup required. While both methods support customization, DTG stands out as a more cost-effective option for low quantities.

10. Application Versatility

DTG printing is suitable for a wide range of products besides t-shirts. It can be used to print hoodies, tote bags, and other cotton items. This versatility makes DTG printing a valuable tool for businesses with diverse printing requirements. On the other hand, sublimation printing can be used for a wide variety of products like mugs, mouse pads, and phone cases. Both DTG and sublimation printing techniques offer comprehensive solutions for promotional merchandise.

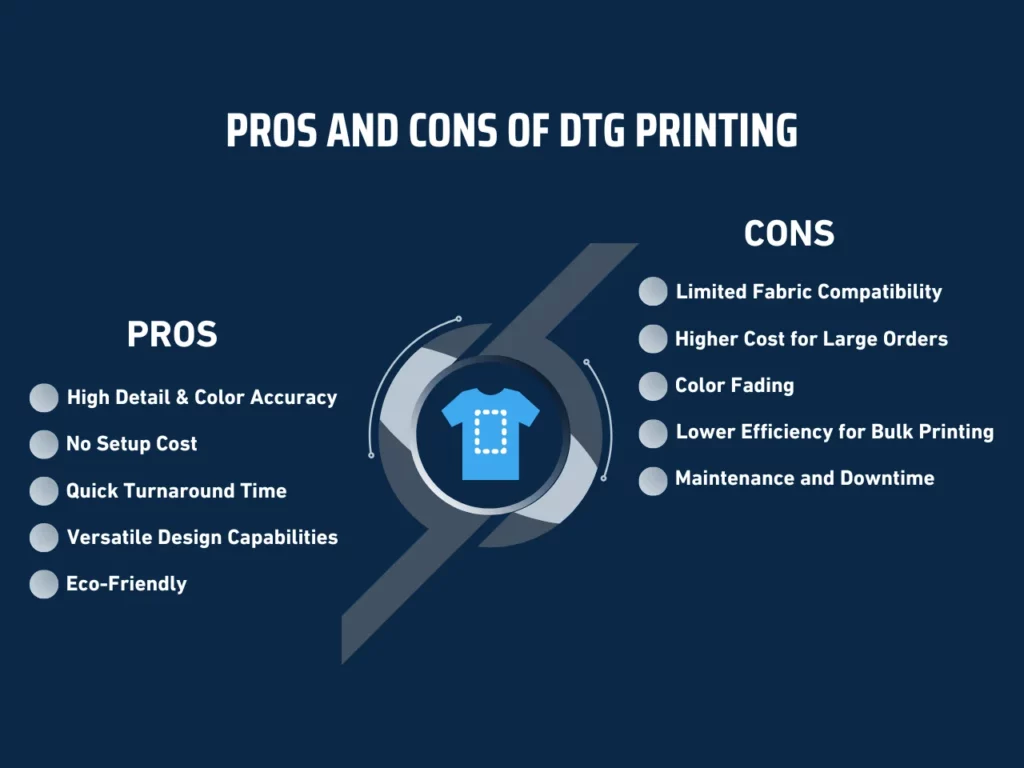

Pros and Cons of DTG Printing

Direct-to-Garment (DTG) printing has gained popularity for its ability to produce detailed designs on t-shirts. Understanding the pros and cons of DTG printing helps businesses make informed decisions about their promotional products.

Pros of DTG Printing

DTG printing offers several advantages, making it a preferred choice for many businesses.

- High Detail and Color Accuracy: DTG printing produces prints with fine details and accurate colors, making it ideal for complex designs and photographs.

- No Setup Cost: Unlike other printing methods, DTG requires no setup cost, making it cost-effective for small batches and custom orders.

- Quick Turnaround Time: The process allows for rapid production, enabling businesses to fulfill orders quickly and efficiently.

- Versatile Design Capabilities: DTG printing supports a wide range of colors and gradients, providing flexibility in design choices.

- Eco-Friendly: DTG uses water-based inks, which are environmentally friendly and safe for use on clothing.

Cons of DTG Printing

Despite its benefits, DTG printing has some limitations that businesses should consider.

- Limited Fabric Compatibility: DTG works best on cotton fabrics but is limited to other materials like polyester.

- Higher Cost for Large Orders: While cost-effective for small batches, DTG printing can become expensive for large quantities compared to other methods.

- Color Fading: DTG prints may fade after multiple washes, reducing the longevity of the design.

- Lower Efficiency for Bulk Printing: The process can be slower for large orders, impacting the overall production time.

- Maintenance and Downtime: DTG printers require regular maintenance, which can lead to downtime and additional costs.

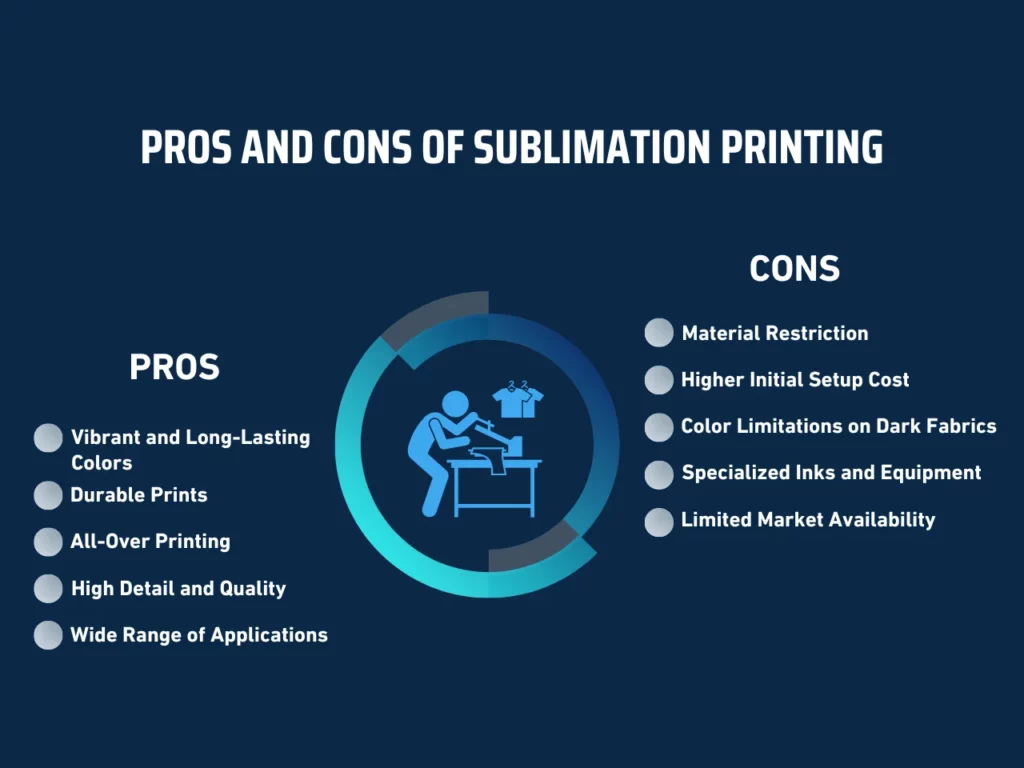

Pros and Cons of Sublimation Printing

Sublimation printing offers unique advantages, making it a popular choice for businesses seeking high-quality promotional products. Understanding its pros and cons helps in making informed decisions.

Pros of Sublimation Printing

Sublimation printing provides several benefits that make it appealing for many applications.

- Vibrant and Long-Lasting Colors: Sublimation produces bright, vivid colors that remain vibrant even after multiple washes.

- Durable Prints: The dye becomes part of the fabric, ensuring prints do not crack, peel, or fade over time.

- All-Over Printing: Sublimation allows for seamless, all-over designs, covering the entire fabric surface.

- High Detail and Quality: The process captures intricate details and fine lines, perfect for complex, high-resolution images.

- Wide Range of Applications: It is suitable for various products, including t-shirts, mugs, and other promotional items, offering versatility.

Cons of Sublimation Printing

Despite its advantages, sublimation printing has some limitations that should be considered.

- Material Restriction: Sublimation printing works excellently on polyester fabrics. But, it cannot be used on other materials like cotton or silk. This method is limited to polyester or polymer-coated surfaces.

- Higher Initial Setup Cost: The costs of setting up sublimation printing can be high. You need specialized equipment and supplies, which raises the initial investment.

- Color Limitations on Dark Fabrics: Colors may appear dull on dark fabrics with this technique. The vibrancy of designs gets reduced on dark-colored materials.

- Specialized Inks and Equipment: Sublimation requires specific inks and printers made for this process. These items cost more and need proper maintenance over time.

- Limited Market Availability: Not all printing shops provide sublimation services. This availability issue can make it harder for businesses to access this method.

Key Takeaway

Choosing the right printing method impacts business success. When comparing DTG vs sublimation, businesses must consider fabric types and design needs. DTG, or Direct-to-Garment, suits small batches and detailed designs on cotton. Sublimation excels with polyester fabrics, offering vibrant, all-over prints.

Businesses must consider the differences between DTG vs sublimation to determine the best fit for their products. DTG suits custom designs and small orders, while sublimation excels in producing high-quality, durable prints for large quantities of polyester. The choice impacts production efficiency, cost, and the overall quality of the promotional products.

Looking for a printing method that suits your business better? Scalable Press provides comprehensive printing solutions tailored to your needs. Explore more resources on our website and see how we compare Printful and Printify. Visit our website or explore our product catalog to learn more.