Apparel printing methods are essential in custom apparel production, influencing everything from cost to the quality of the final product. Comparing the costs of traditional methods like screen printing with modern digital apparel printing empowers businesses to choose the best option tailored to their design needs. Each method offers unique advantages, depending on the printing process and design requirements, ensuring optimal results for specific file types.

At Scalable Press, we provide an extensive print vendor network, offering a range of sizes and high-quality prints at an affordable price. Our services include DTG printing, screen printing, and embroidery, all designed for quick turnaround and excellent service. We leverage inkjet technology and digital printers to produce full-color designs with precision, meeting the diverse demands of our clients.

With our experience in tailored apparel solutions, we’ve crafted this guide to compare the costs between traditional and digital apparel printing methods. By the end, you’ll be equipped to choose the most cost-effective printing process for your business needs.

Let’s dive in!

What Is Traditional Apparel Printing

Traditional apparel printing is a method used for garment printing, primarily using screen printing techniques. It’s perfect for producing vibrant, full-color designs and logos on items like T-shirts, hoodies, tank tops, and sweatshirts. Businesses often choose traditional printing for family reunion shirts and jerseys, where design size and quality are paramount. This method requires precision with ink and artwork to deliver high-quality output.

While traditional apparel printing is cost-effective for large orders, it may not be as economical for smaller quantities due to its extensive setup and processing. These factors can affect shipping costs and turnaround times. However, it remains an excellent service for full-color designs on ringspun cotton and other garments.

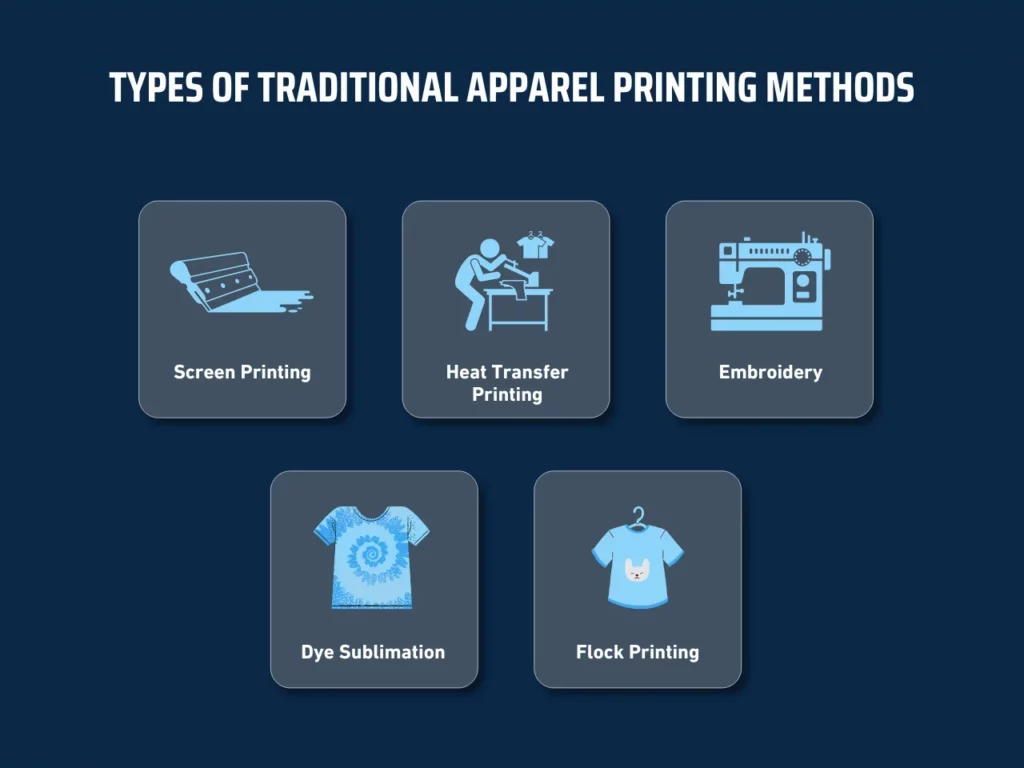

Types of Traditional Apparel Printing Methods

Traditional apparel printing methods have stood the test of time, offering reliability and high-quality results, especially for large-scale orders. Knowing the different types of traditional apparel printing methods can help businesses choose the most suitable technique for their needs.

- Screen Printing: This method involves using a stencil (or screen) to apply layers of ink to the fabric. Known for its durability and vibrant colors, screen printing is ideal for bulk orders with simple designs.

- Heat Transfer Printing: This technique transfers designs onto fabric using heat and pressure. It’s versatile and works well for producing small quantities or intricate designs.

- Embroidery: Although not a printing method per se, embroidery involves stitching designs directly onto fabric using thread. It’s commonly used for logos on corporate apparel.

- Dye Sublimation: Often used on polyester and synthetic materials, dye sublimation involves turning solid dye into gas without passing through a liquid state. This method allows for all-over designs with rich, vibrant colors.

- Flock Printing: Adding a velvety texture, flock printing applies fibers to the fabric, enhancing the tactile appeal of garments. It’s a great choice for creating standout logos or unique custom apparel.

Each of these traditional apparel printing methods provides distinct advantages tailored to different project requirements. Whether choosing screen printing for large, simple designs or dye sublimation for vibrant, full-color prints, businesses can select a method that aligns with their goals and budget.

What Is Digital Apparel Printing

Digital apparel printing revolutionizes garment printing by leveraging advanced inkjet printer technology. This cutting-edge method prints vibrant, high-color designs directly onto garments like tees, hoodies, and tank tops without the need for screens, ensuring efficiency and reduced setup costs. It’s perfect for detailed digital images and ideal for small orders, offering flexibility and cost-effectiveness.

With digital printing, you can achieve stunning results on ringspun cotton, making it the go-to choice for intricate logos and full-color designs. Businesses often prefer digital printing for smaller orders, next-level DTG prints, and short-run projects. This process saves much money and time compared to traditional methods, making it ideal for quick turnarounds and custom orders.

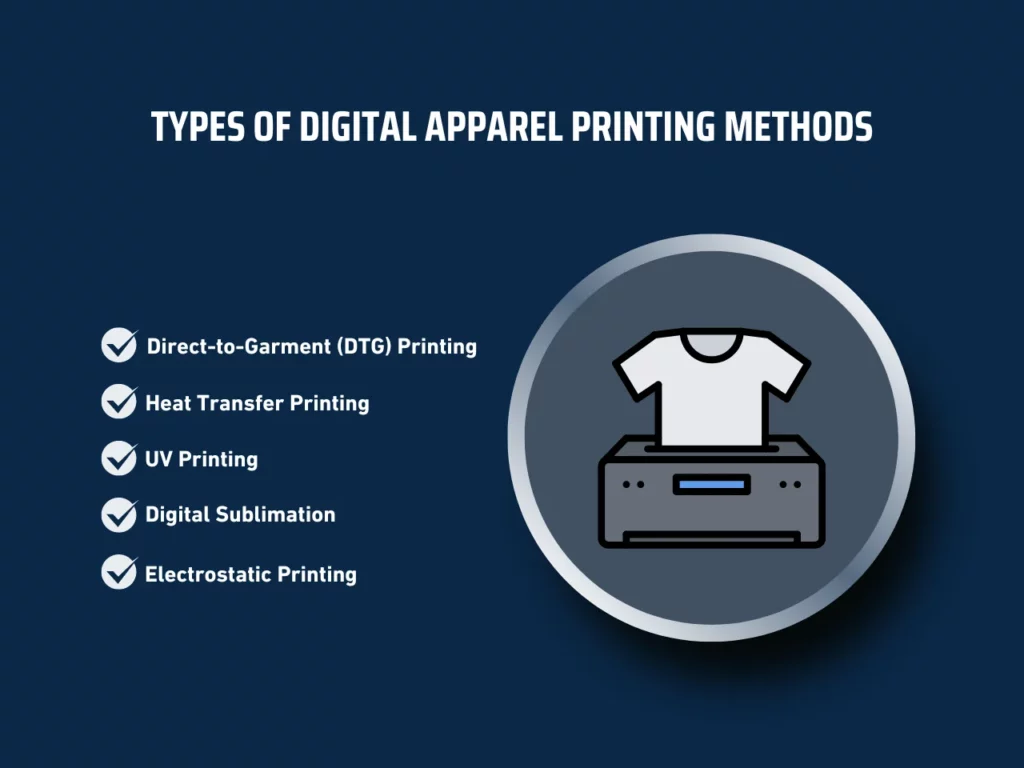

Types of Digital Apparel Printing Methods

Digital printing is a go-to solution for businesses seeking flexibility and cost-effectiveness, especially when handling complex or customized designs. Understanding the different types of digital apparel printing methods can help businesses make informed decisions to achieve the best results for their promotional products.

- Direct-to-Garment (DTG) Printing: DTG printing involves using inkjet technology to print designs directly onto fabric. This method is ideal for small orders and detailed artwork. It allows for vibrant colors and high-resolution prints, making it a popular choice for custom apparel.

- Heat Transfer Printing: This versatile digital method transfers designs from specialized papers or films onto fabrics, allowing for full-color prints and detailed designs. It’s perfect for short runs and unique, one-off pieces.

- UV Printing: Leveraging ultraviolet light to instantly cure or dry the ink as it prints, UV printing delivers exceptional durability and vivid colors across various materials, including textiles. This method is ideal for both hard surfaces and fabrics.

- Digital Sublimation: Like dye sublimation, digital sublimation prints designs onto a transfer paper using special inks. The heat transfer process infuses the design into the fabric, resulting in vibrant, long-lasting colors, particularly effective for polyester fabrics.

- Electrostatic Printing: Electrostatic printing involves applying a static charge to attract toner particles to the fabric, which are then fused with heat. This method allows for high-resolution prints and is suitable for small and large runs.

Each digital apparel printing method offers unique advantages. Choosing the right technique depends on factors like design complexity, fabric type, and order size. Businesses should evaluate these methods to find the best fit for their printing needs.

Cost Comparison: Traditional vs. Digital Printing

Assessing the cost implications is crucial when selecting an apparel printing method. Traditional and digital printing methods each have distinct pricing structures shaped by factors like setup, materials, and production volume. This cost analysis breaks down the financial aspects of both approaches, helping you make an informed decision.

1. Initial Setup Costs

Traditional apparel printing methods, like screen printing, often demand significant initial setup investments. Creating screens and setting up presses can cost anywhere from $500 to $2,000, depending on the number of colors and designs. In contrast, digital apparel printing typically involves lower setup costs. With direct-to-garment (DTG) printers priced between $10,000 and $30,000, the need for screens and associated fees is eliminated, simplifying the initial investment process.

2. Material and Ink Costs

When it comes to materials and ink, traditional printing methods can be pricier. Screen printing involves various inks and materials that might reach up to $3 per shirt. Meanwhile, digital apparel printing often uses specialized inks, costing about $1.50 to $2 per shirt. Although digital inks may have a higher per-unit price, they require fewer materials and less setup, creating a balanced overall cost profile.

3. Labor and Time Costs

Labor and time costs are another critical difference. Traditional apparel printing requires manual setup and handling, which drives up labor expenses. For example, producing a batch of 100 shirts can take several hours and cost approximately $200 in labor. In comparison, digital apparel printing automates much of the process, drastically cutting labor costs. The same batch can be completed in a fraction of the time, with labor costs potentially as low as $50.

4. Equipment Maintenance and Lifespan

When it comes to equipment maintenance and lifespan, traditional printing equipment like screen presses, generally has lower maintenance costs but may not last as long, often needing frequent repairs. On the other hand, digital apparel printing equipment, while often more expensive to maintain, offers longer lifespans with fewer breakdowns. High-end DTG printers, for instance, may incur maintenance costs around $1,000 annually but offer superior longevity and reliability.

5. Customization and Small Batch Costs

Digital apparel printing excels in customization and small-batch production, offering flexibility without high setup fees. Traditional methods, such as screen printing, can become costly for small orders due to setup charges. Digital printing accommodates small runs and personalized designs at minimal additional costs, making it an ideal choice for businesses needing unique or limited-edition items.

Factors Influencing the Cost Between Traditional and Digital Printing

Several factors influence overall costs when comparing digital apparel printing with traditional methods. Understanding these factors helps businesses make informed decisions based on their needs and budget. Here are five key factors:

1. Order Volume

Digital apparel printing offers cost advantages for small to medium-sized orders. The setup costs are minimal, making it ideal for short runs or custom designs. In contrast, traditional printing methods like screen printing typically have higher setup costs. They become more cost-effective with larger volumes as the setup costs are spread over more items. For large-scale orders, traditional methods can offer a more economical solution.

2. Design Complexity

The complexity of the design affects the cost differently for both digital apparel printing and traditional methods. Digital printing excels at handling intricate designs and gradients without additional costs. Traditional printing, however, can incur higher costs for complex designs due to increased setup time and the need for specialized screens. Digital printing remains the cost-efficient choice for highly detailed or multi-colored designs.

3. Turnaround Time

Speed determines the cost differences between traditional and digital apparel printing. Digital printing offers rapid processing, leading to faster turnaround times and reduced labor expenses. This efficiency translates to quicker deliveries, which is a competitive advantage. On the other hand, traditional printing methods, with their manual setup and processing, often require more time, potentially increasing costs when expedited services are necessary.

4. Material and Ink Costs

Material and ink costs differ significantly between traditional and digital apparel printing. Digital printing uses specialized inks that, while potentially more expensive, yield higher-quality prints with minimal waste. In contrast, traditional methods like screen printing benefit from bulk ink purchasing and lower material costs, though setup and cleanup can add to expenses. The choice of inks and materials influences the overall cost, depending on the method used.

5. Equipment Maintenance and Lifespan

The maintenance and lifespan of printing equipment influence long-term costs. Digital printing machines, though requiring regular maintenance and occasional repairs, often have an extended lifespan when properly maintained. Traditional printing equipment, such as screen printers, also demands upkeep, though maintenance needs can vary. Evaluating the maintenance requirements and equipment lifespan helps understand the total cost implications.

Key Takeaway

Choosing between digital and traditional apparel printing requires a careful evaluation of your business’s specific needs. Digital apparel printing shines with its flexibility and efficiency, especially for smaller runs and intricate designs. Its quick turnaround time and ability to handle detailed graphics make it a strong option for custom projects. Meanwhile, traditional methods may offer more cost-effective solutions for larger orders with simpler designs.

Understanding the nuances of each project is crucial. Traditional printing methods can be more economical for businesses that regularly order in bulk or need straightforward designs. Conversely, digital apparel printing can deliver more value for businesses needing fast production and high customization. Each method comes with its cost structure and benefits, making it essential for businesses to evaluate their priorities and budget constraints.

Are you curious about how much embroidery costs or DTG pricing? Scalable Press, is here to help you find the best printing solution tailored to your needs. Our platform provides a seamless experience with competitive pricing and no minimum orders. Explore our product catalog to see how we can meet your printing needs with efficiency and quality.