Businesses seeking cost-effective branding solutions often turn to contract embroidery for its flexible pricing and superior quality. Contract embroidery offers businesses high-quality promotional products with customized designs. With contract embroidery pricing that accommodates businesses of all sizes, you can enhance your promotional strategy efficiently and effectively.

Scalable Press offers a comprehensive solution for contract embroidery needs. Our extensive print vendor network, single order management dashboard, and modern software interfaces streamline the process. Competitive pricing and no minimum orders make our services accessible to businesses of all sizes. We ensure high-quality products and fast turnaround times, providing a cost-effective solution that suits any budget.

Leveraging our insights into the embroidery business, we’ve created this guide to explore key factors influencing contract embroidery pricing. We will explore pricing strategies for embroidery services, setting wholesale prices, and the impact of order volume and turnaround times. At the end of this blog, you will understand how to charge for embroidery, manage bulk orders, ensure customer satisfaction, and make informed decisions about your embroidery services.

Let’s jump in!

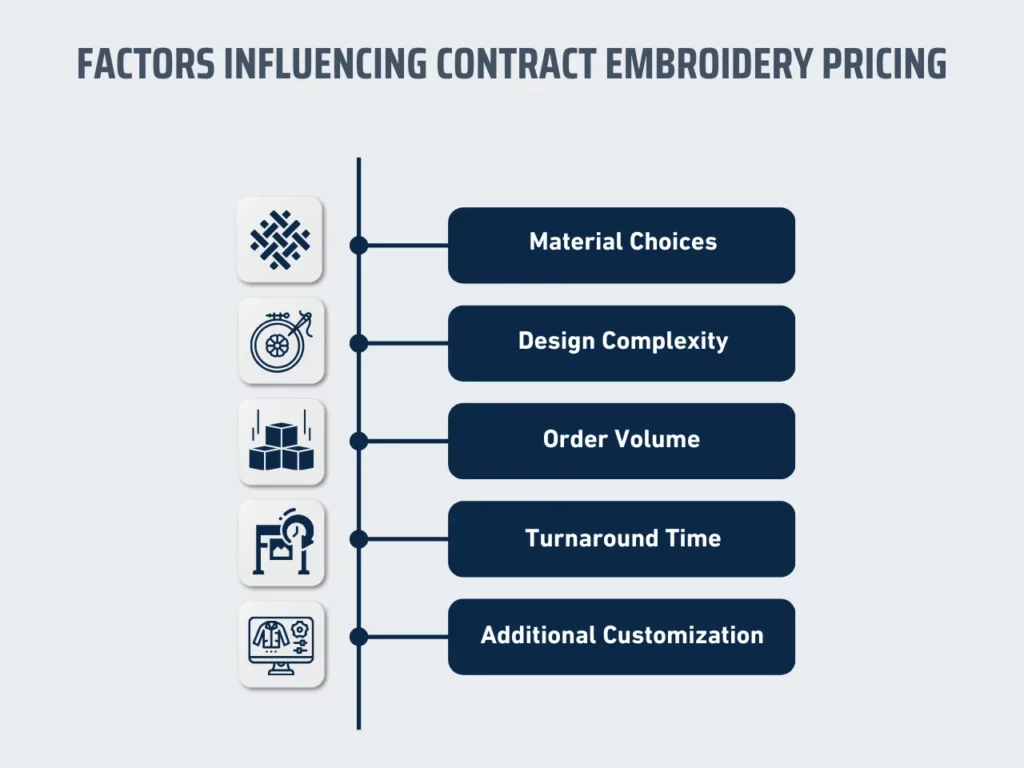

Factors Influencing Contract Embroidery Pricing

Contract embroidery pricing is influenced by several key factors that can significantly impact the cost of your embroidery projects. Understanding these factors is essential for budgeting and making informed decisions. Let’s explore five major aspects that determine the pricing of contract embroidery services and help you manage your expenses effectively.

1. Material Choices

The choice of materials significantly impacts embroidery prices. Different fabrics require specific handling and machine settings, affecting the overall cost. For instance, delicate fabrics like silk necessitate careful handling and specific thread types, which might increase the contract embroidery pricing. Conversely, sturdy materials like cotton may be less expensive to embroider. The type of thread used—polyester, cotton, or specialty threads like metallics—also influences the price. Polyester threads are generally cheaper, while specialty threads add to the cost.

2. Design Complexity

The complexity of the embroidery design directly affects how much embroidery costs. Designs with intricate details require more time and higher stitch counts, increasing the price. Simple logos with fewer colors and minimal details will cost less.

Businesses often calculate how to charge for embroidery based on the number of stitches required to complete the design. Higher stitch counts translate to more machine time and higher contract embroidery pricing. A design with 15,000 stitches will be more expensive than one with 5,000 stitches due to the increased labor and time.

3. Order Volume

The volume of the order plays a crucial role in determining embroidery prices. Larger orders often benefit from volume discounts, reducing the per-unit cost. Embroidery companies may offer tiered contract embroidery price structures where the cost per item decreases as the order size increases. For instance, an order of 500 items will typically be cheaper per unit than an order of 50. Understanding this contract embroidery pricing structure is vital when planning large-scale embroidery projects, as it can lead to significant cost savings.

4. Turnaround Time

The required turnaround time can impact how much embroidery costs. Rush orders usually come with a premium due to the need for expedited processing and potential overtime work. Standard orders allow better scheduling and resource management, lowering contract embroidery pricing. Businesses needing faster delivery should be prepared for higher prices. That said, planning embroidery projects well in advance can help avoid rush fees and keep embroidery prices more manageable.

5. Additional Customization

Additional customization options, such as thread color changes and special effects, can influence embroidery contract embroidery pricing. Each color change in a design requires stopping the machine, rethreading it, and calibrating it for the new color, which adds to the labor and time involved.

Moreover, techniques like 3D puff embroidery or appliqué add complexity and cost. When calculating how to charge for embroidery, these customizations are factored into the overall price, ensuring that the final product meets the desired specifications without compromising quality.

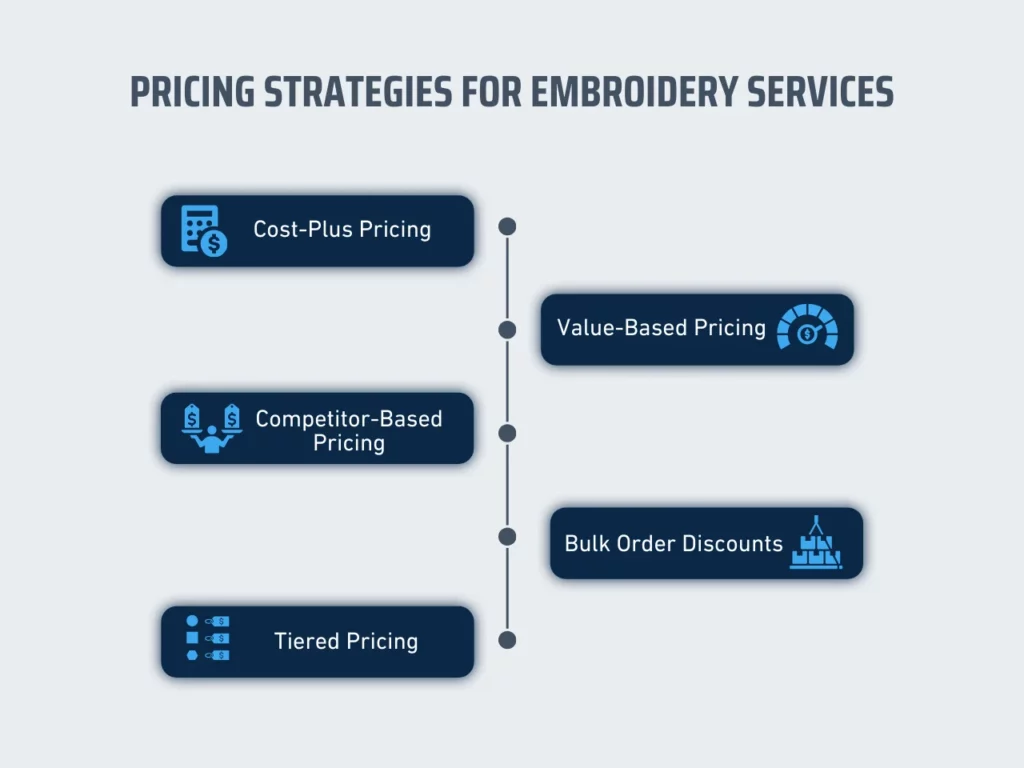

Pricing Strategies for Embroidery Services

Establishing effective pricing strategies is essential for embroidery companies. Proper pricing ensures profitability and aligns with market expectations and customer satisfaction. Below, we explore five pricing strategies for embroidery services, focusing on key factors such as stitch count, embroidery machine maintenance, thread colors, and more.

1. Cost-Plus Pricing

Cost-plus contract embroidery pricing involves calculating the total order cost by adding all expenses. This includes thread colors, embroidery machine maintenance, and the digitizing fee. Once these costs are determined, a markup percentage ensures profit. For example, if the total order cost for custom embroidery is $50, adding a 20% markup would set the price at $60. This method guarantees that all costs are covered while securing a profit margin.

2. Value-Based Pricing

Value-based contract embroidery pricing sets prices based on the perceived value rather than the actual cost. This approach requires understanding the unique value your embroidery work offers. Factors such as the quality of work, number of stitches, and customer service play a crucial role. Customers may be willing to pay a premium if they perceive the embroidery design as high-quality and unique. This strategy can differentiate your services from competitors who focus solely on cost.

3. Competitor-Based Pricing

Competitor-based pricing involves analyzing the prices set by other embroidery companies. By understanding the market rates, you can position your services competitively. For instance, if competitors charge $10 per inch of embroidery, you might set your price slightly lower or higher depending on the quality and durability of your embroidery work. This strategy ensures your contract embroidery pricing remains competitive while reflecting the stitch type and overall quality.

4. Bulk Order Discounts

Offering structured discounts for large orders or repeat customers can significantly enhance customer loyalty and increase order volume. For example, a 10% discount for orders over 100 garments can reduce the cost per garment and encourage more significant purchases. This approach attracts large orders and fosters long-term client relationships, ensuring repeat business.

5. Tiered Pricing

Tiered contract embroidery pricing establishes different price levels based on order size and complexity. Prices adjust according to factors like the number of colors, quality of accessories, and the type of logo or artwork required. For instance, a basic tier might include simple designs with fewer thread colors, while a premium tier could offer complex logos with multiple colors and higher stitch counts. This flexibility allows customers to choose a package that fits their needs and budget.

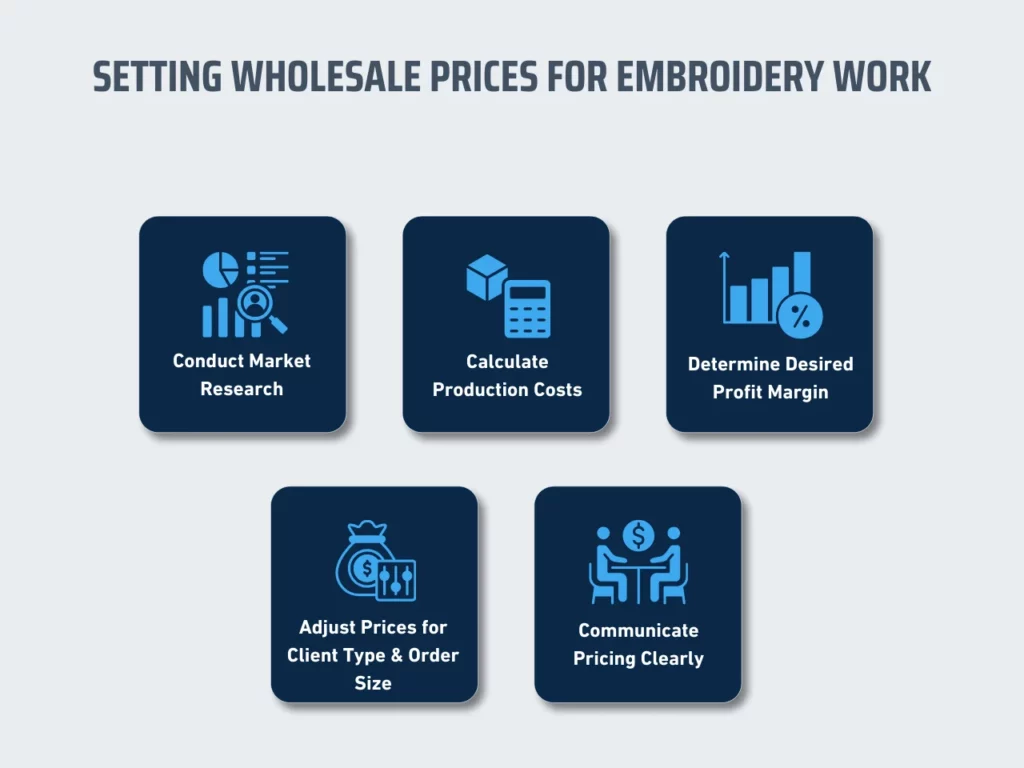

Setting Wholesale Prices for Embroidery Work

Setting wholesale prices for embroidery work requires careful consideration of various factors to ensure profitability and competitiveness. Following a structured approach, you can determine fair and profitable wholesale prices. Here are five essential steps to establish the right pricing strategy for your embroidery business:

Step 1: Conduct Market Research

Conduct market research to set competitive prices for contract embroidery. This involves analyzing competitors, identifying market trends, and understanding customer expectations. Research helps ensure your pricing aligns with industry standards and customer demand.

Here are the steps to conduct effective market research:

- Analyze Competitors: Examine local and online contract embroidery businesses to understand pricing strategies.

- Identify Market Trends: Stay updated with industry trends to gauge pricing shifts and demand fluctuations.

- Assess Customer Willingness: Survey potential clients to determine what they are willing to pay for contract embroidery services.

Incorporating these strategies into your pricing strategy ensures you stay competitive. Regularly update your market research to stay informed about new trends and changes in client preferences. Effective market research is the foundation for setting profitable prices for contract embroidery services.

Step 2: Calculate Production Costs

Accurately calculating production costs ensures contract embroidery pricing remains fair and profitable. Include material costs such as threads, fabrics, and stabilizers. These form the foundation of your pricing strategy. Consider labor costs, calculating the hourly wage of workers and the time required for various embroidery tasks. Additionally, factors in overhead costs like equipment maintenance, electricity, and rent.

Don’t forget to determine the hourly labor cost rate and multiply it by the time needed for each type of embroidery work. This calculation should include setup, stitching, and finishing times. Accurate labor cost estimation guarantees fair wages and maintains profitability. Regularly review and update these costs to reflect changes in material prices or labor rates. This step ensures contract embroidery services remain competitive while sustaining business growth.

Step 3: Determine Desired Profit Margin

Setting clear profit goals for contract embroidery ensures sustainability and growth. Aim for a profit margin between 20% and 50%, and consider your industry standards and business objectives. Calculate profit margins based on production costs, including materials and labor.

You can offer tiered pricing based on order size. Larger orders for contract embroidery can be priced lower per item to attract bulk buyers, maintaining overall profitability. Flexibility with pricing helps secure large contracts while keeping your embroidery business competitive. Adjust prices to reflect changes in production costs and market conditions regularly.

Step 4: Adjust Prices for Client Type and Order Size

Adjusting prices for client type and order size ensures competitive and profitable contract embroidery services. Different clients have unique needs and purchase patterns, necessitating tailored pricing strategies. A flexible approach to pricing will help attract a diverse clientele while maximizing profit margins.

Here are the key factors to consider:

- Client Segmentation: Different clients require distinct pricing models. Retail buyers often order in small quantities and expect premium quality. Wholesale buyers look for bulk discounts. Corporate clients usually demand large orders with custom designs.

- Order Size: Larger orders often benefit from a lower price per item to encourage bulk purchasing. Smaller orders can maintain higher prices to cover production costs effectively.

- Market Demand: Adjust prices based on demand fluctuations. Increase prices during high-demand seasons to maximize revenue. Offer discounts during off-peak times to maintain steady business.

Review and adjust pricing strategies regularly to remain competitive in the contract embroidery market. Transparent pricing and client-specific adjustments build trust and encourage repeat business, ensuring your contract embroidery services stay profitable and client-focused.

Step 5: Communicate Pricing Clearly

Communicate your pricing for the services rendered to ensure clients understand all contract embroidery pricing components. Break down material costs, labor charges, and additional fees. Provide detailed estimates before starting work. Make sure to sign contracts to document all pricing agreements for clarity and trust.

Offering regular reviews and updates on pricing is a great way to reflect changes in production costs or market conditions. Tailor communication to each client type, emphasizing the value and quality of your contract embroidery services. This builds strong client relationships and fosters repeat business, keeping your pricing competitive and fair.

Key Takeaway

Understanding contract embroidery pricing helps businesses set accurate budgets. Consider factors like material quality, design complexity, and order volume. Evaluating these elements ensures you set competitive and fair prices for your clients. Transparent communication about these components fosters trust and long-term relationships.

Assess pricing strategies by analyzing market trends and competitor rates. Use cost-plus or value-based pricing aligned to your business goals. Offering discounts for bulk orders or repeat customers can boost client retention and sales. Regularly review and adjust your pricing to stay competitive and profitable.

Ready to streamline your contract embroidery pricing? Scalable Press offers competitive pricing with no minimum orders, ensuring high-quality products and fast turnaround times. Visit our homepage to learn about DTG pricing and explore our product catalog to find the perfect solution for your business needs.