Committing errors in the wholesale screen printing process can result in costly delays, subpar products, and unsatisfied customers. Improper screen tension, incorrect squeegee angle, or selecting the wrong printing technique can cause a distorted image or excess ink on the edges of the print. Other screen printing problems, like air bubbles, pinholes, and ink spreading, further add to compromising the print quality, leading to increased costs and missed deadlines.

Scalable Press offers an extensive print vendor network and a user-friendly dashboard to manage every printing job. Our screen printing machines use advanced techniques and precise mesh count to ensure high-quality results. We optimize ink viscosity and control the printing speed to achieve the best results on any substrate. Our commitment to excellence ensures a seamless experience from start to finish, regardless of your print shop size or order volume.

Implementing our industry expertise, we’ve crafted this guide to help you avoid common screen printing mistakes. We will equip you with the knowledge to achieve the best results. By the end, you will have actionable tips to avoid common screen printing problems and ensure your wholesale screen printing job succeeds.

Let’s get started!

8 Mistakes to Avoid When Wholesale Screen Printing Orders

Even small errors can lead to costly delays and customer dissatisfaction when managing wholesale screen printing orders. To ensure your orders are processed smoothly and efficiently, it’s crucial to avoid common pitfalls. Here are 8 key mistakes to watch out for to keep your projects on track:

Mistake 1: Not Understanding the Screen Printing Process

A lack of understanding of the screen printing process can lead to several errors in design and production. When businesses are unfamiliar with the technique, they might use more or less ink, which can affect the quality of the printed image. Misunderstandings can also occur regarding the mesh screen, flood bar, and the appropriate print speed for the job.

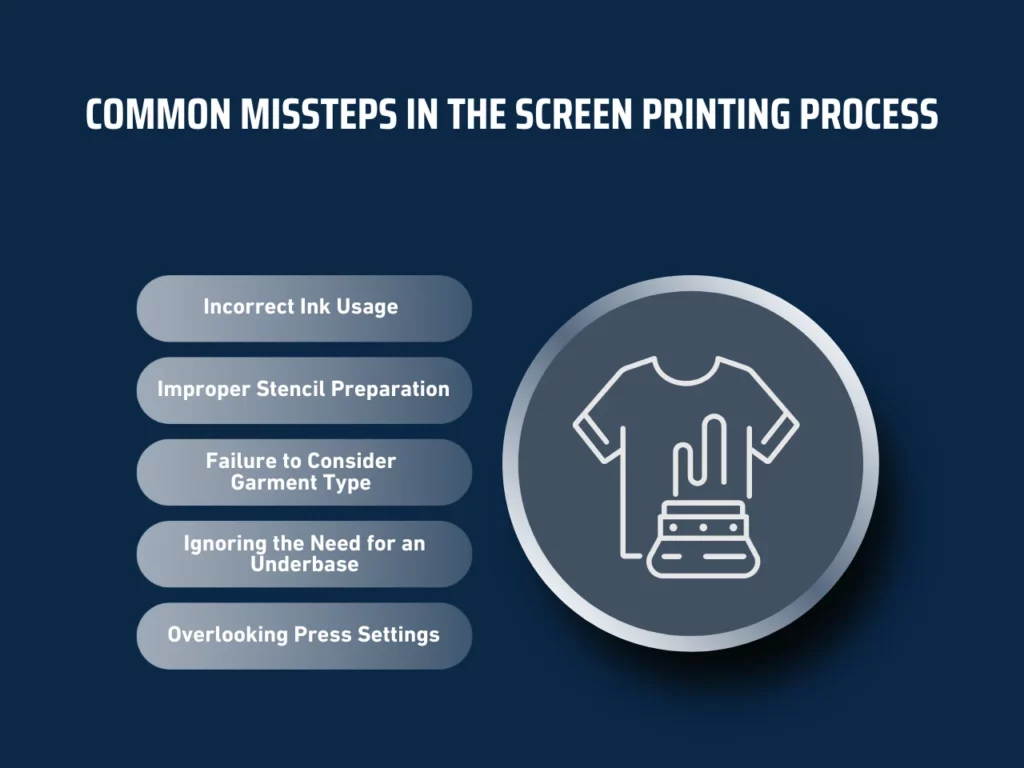

Here are the common missteps in the screen printing process:

- Incorrect Ink Usage: Using much or less ink can ruin the image area.

- Improper Stencil Preparation: A poorly made stencil affects the final screen print.

- Failure to Consider Garment Type: Different tees and fabrics, like burnout tees, require different techniques.

- Ignoring the Need for an Underbase: An underbase layer ensures vibrant colors on dark garments.

- Overlooking Press Settings: Incorrect printing press settings can cause press sheet issues.

Understanding these aspects of screen printing helps avoid issues like press sheet sticks, poor stock, and contamination. Follow screen printing best practices, such as proper screen preparation, curing, and ink application, to ensure accurate registration, proper coating, and optimal printed image quality.

Mistake 2: Poor Quality Artwork

Poor quality artwork can lead to disappointing results in wholesale screen printing. Screen printers need high-resolution images to ensure clarity and precision in the final product. Low-quality images often result in unclear designs that fail to achieve the desired impact.

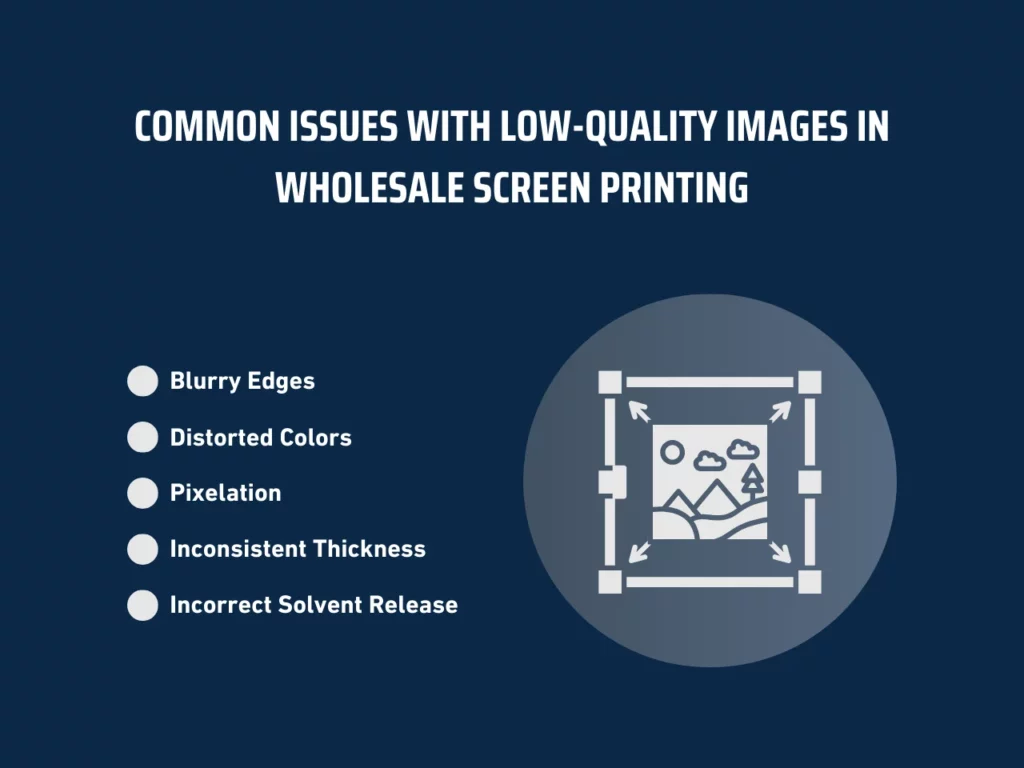

Common issues with low-quality images in wholesale screen printing include:

- Blurry Edges: Low-resolution images cause blurry edges, reducing the sharpness of the print.

- Distorted Colors: Inadequate image quality may cause incorrect colors when applying the second color.

- Pixelation: Enlarging low-quality images leads to pixelation, especially in large-area prints.

- Inconsistent Thickness: Poor quality artwork affects the uniformity of ink film thickness, leading to uneven coverage.

- Incorrect Solvent Release: The image quality affects solvent release, causing drying screen printing ink issues.

A well-prepared image enhances the final print, achieving the intended result in wholesale screen printing. Make sure to have a better alignment with the screen printer’s capabilities. Use professional tools for image preparation optimized for the correct coater, pallet, and retarder settings. This prevents problems like lint, improper emulsion thickness, and misapplication of silkscreen additives.

Mistake 3: Ignoring Minimum Order Quantities

Minimum order quantities play a crucial role in wholesale screen printing. Understanding how they work helps ensure your order meets the printing company’s requirements. Businesses must meet these quantities to proceed with production, which typically depends on the printing method and equipment used.

It is important to meet minimum order quantities to ensure pricing and order feasibility. Here are the impacts:

- Higher Costs: Smaller orders often incur higher per-unit costs.

- Limited Options: Vendors may offer fewer customization options for smaller orders, limiting your design choices.

- Extended Turnaround Times: Smaller orders might not be prioritized, causing delivery delays.

- Potential Order Rejection: Some printers might reject orders that don’t meet the minimum, leading to project delays.

- Inconsistent Quality: Smaller runs may result in inconsistent print quality, affecting the final product’s appearance.

Always check the minimum order requirements before placing your wholesale screen printing order to avoid these issues. Proper planning ensures your project remains on schedule, within budget, and meets the necessary production standards.

Mistake 4: Overlooking the Type of Ink Used

Choosing the wrong ink can dramatically impact the durability and appearance of your wholesale screen printing order. Incorrect ink selection may lead to prints that fade quickly, crack, or fail to adhere correctly to the fabric. This compromises the quality of the final product and can result in unsatisfied customers.

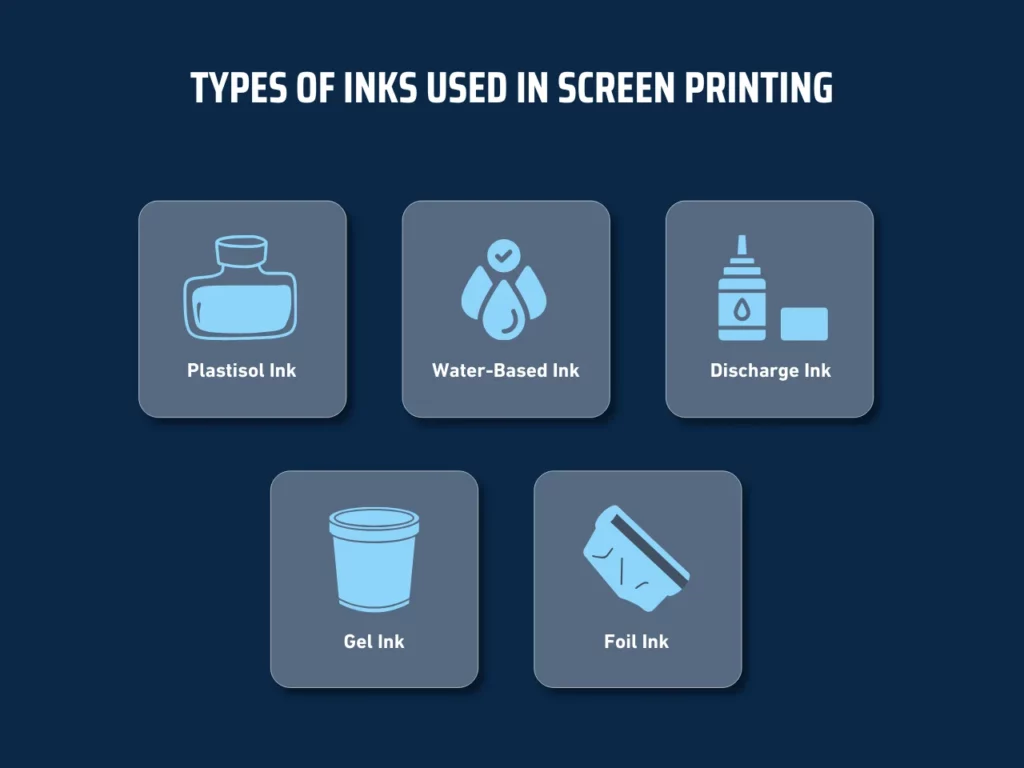

Use these top-tier types of inks for screen printing:

- Plastisol Ink: Known for its vibrant colors and durability, it may feel heavy on the fabric.

- Water-Based Ink: Offers a softer feel and eco-friendliness but may need to work better on dark fabrics.

- Discharge Ink: Ideal for creating soft prints on dark garments but requires precision in the process.

- Gel Ink: Adds a glossy finish and texture but is best used for specific designs.

- Foil Ink: It creates a metallic finish, perfect for special effects but prone to peeling if not applied correctly.

To avoid issues, always consider the fabric type and desired finish. Consult with your printer to ensure your ink choice aligns with your project goals. Reviewing proofs and conducting tests will help ensure the final product meets your expectations.

Mistake 5: Not Considering the Fabric Type

Selecting the correct fabric holds utmost significance in wholesale screen printing. The fabric chosen directly impacts the final product’s quality, durability, and appearance. Ignoring this factor can lead to poor print results, causing dissatisfaction and potential rework.

Different fabrics react uniquely to screen printing. Here are the key differences:

- Cotton: Absorbs ink well, providing vibrant prints. However, it may shrink after washing.

- Polyester: Resists shrinking and maintains its shape well but requires special inks to prevent dye migration, which can cause colors to bleed.

- Blends: Offer a balance between cotton and polyester but might cause ink absorption issues that can affect print clarity.

- Nylon: Requires specific inks to achieve adhesion and is typically used for items like jackets and bags. It often needs a specialized printing process.

- Tri-Blends (e.g., cotton-polyester-rayon): Combine three different fibers, which can lead to varying ink absorption rates and make it challenging to achieve consistent print quality.

When selecting the right fabric for your project, consider the following tips:

- Match Fabric to Use: Choose durable fabrics for high-wear items like uniforms or sportswear to ensure longevity and performance.

- Consider Fabric Color: Dark fabrics might require additional layers or specific inks to achieve vibrant and accurate prints and ensure proper adhesion and color fidelity.

- Test Ink Compatibility: Always test inks on a fabric swatch before full production.

- Account for Fabric Texture: Textured fabrics, like fleece, can impact ink adhesion and print clarity. Adjust printing techniques accordingly to maintain quality.

- Evaluate Cost vs. Quality: Balance your budget with the need for high-quality results, ensuring that you achieve the best possible outcome without compromising on durability or appearance.

To avoid mistakes, always communicate fabric choices with your printer, test materials when possible, and seek expert advice. Proper preparation ensures the selected fabric aligns with your desired outcome, leading to a successful screen printing project.

Understanding fabric properties and their impact on the screen printing process significantly enhances product quality, ensuring customer satisfaction and long-term success.

Mistake 6: Failing to Review Proofs Thoroughly

Reviewing proofs before production ensures a successful wholesale screen printing order. Proofs serve as your chance to catch any errors or inconsistencies before the design goes to print. Neglecting this step can lead to costly mistakes that affect the quality and accuracy of the final product.

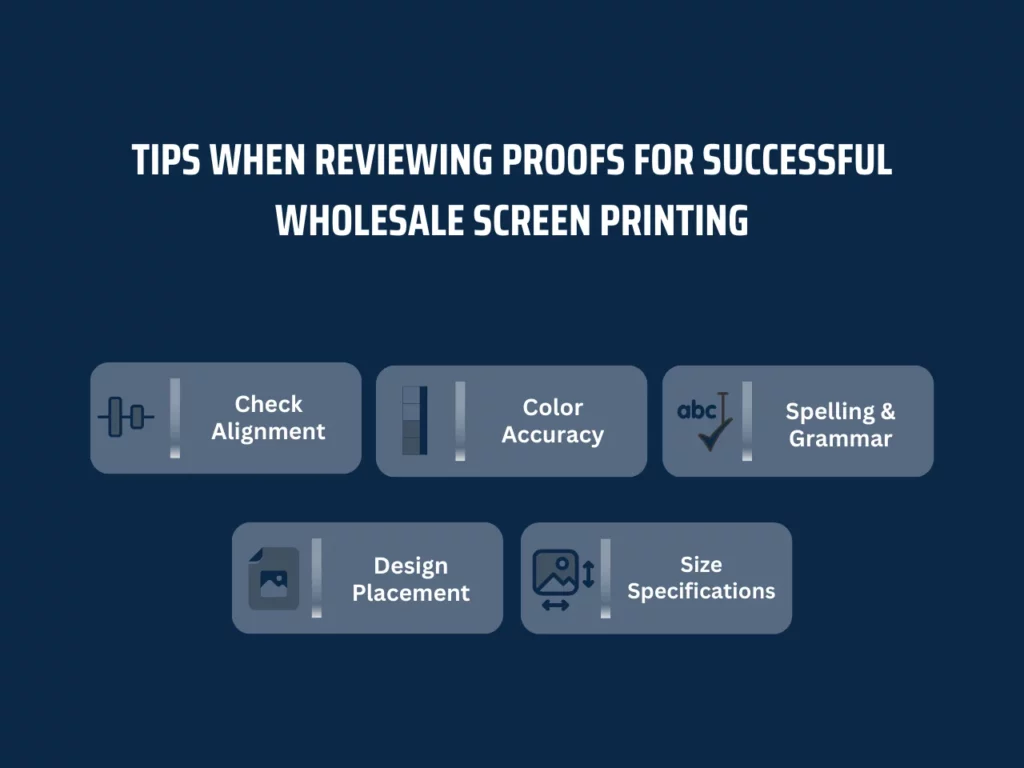

To avoid these issues, consider the following tips when reviewing proofs:

- Check Alignment: Ensure all design elements are properly aligned and centered. Misalignment can affect the overall look and professionalism of the final product.

- Color Accuracy: Confirm that the colors in the proof match your expectations and the intended design. Color discrepancies can alter the visual impact of your design.

- Spelling and Grammar: Carefully review all text for spelling and grammatical errors. Mistakes can detract from the quality and credibility of the final product.

- Design Placement: Verify that the design is accurately positioned on the garment or material. Incorrect placement can lead to an unappealing final product.

- Size Specifications: Ensure the design size adheres to your specifications and fits well within the intended area. Proper sizing is crucial for maintaining design integrity and visual balance.

To avoid errors, take the time to review every proof thoroughly. Involve multiple team members in the process, and consider viewing proofs in different lighting conditions. Don’t rush. Ensure every detail is correct before giving final approval.

Finalizing proofs correctly ensures a smooth production process and a high-quality final product. Avoiding these common pitfalls in wholesale screen printing can save time, money, and stress in the long run.

Mistake 7: Miscommunication with the Printing Company

Miscommunication with the printing company can lead to severe problems in wholesale screen printing projects. Businesses often need help with issues like incorrect colors, wrong sizes, or improper placement of designs. These problems usually arise from unclear or incomplete instructions, resulting in costly mistakes and delays.

Effectively convey your needs and expectations to the printing company. Here are the key steps to follow:

- Provide Detailed Instructions: Clearly outline every aspect of your order, including design specifications, colors, and sizes.

- Confirm Order Details: Before production begins, ensure that both parties agree on the final design and other essential details.

- Keep a Record of Communications: Document all conversations, emails, and agreements to avoid misunderstandings.

- Establish a Point of Contact: Designate one person to handle all communication with the printer to maintain consistency.

- Request Regular Updates: Stay informed about the progress of your order to catch any issues early.

To avoid problems in the wholesale screen printing process, plan your communication strategy carefully. Make sure all instructions are clear and complete, and double-check all details before approving the final proof. Miscommunication can lead to dissatisfaction and wasted resources, resulting in a product that may not meet your expectations or satisfy your customers.

Mistake 8: Overlooking Turnaround Times

Overlooking turnaround times can significantly impact your wholesale screen printing project. Delays lead to missed deadlines, causing a ripple effect across your entire schedule. Time-sensitive projects, such as events or product launches, are particularly vulnerable, potentially leading to unsellable stock or dissatisfied clients. Proper planning and considering turnaround times are essential to ensure your project stays on track.

Here are some tips for planning and ensuring deadlines are met:

- Set Clear Timelines: Establish realistic deadlines that consider all stages of production, from design to delivery.

- Communicate Early: Inform your printing company of your required deadlines as soon as possible to avoid last-minute surprises.

- Allow for Buffer Time: Include extra time in your schedule for unexpected delays or revisions that may arise during the printing process.

- Confirm Turnaround Times: Always verify the turnaround times provided by your printer and ensure they align with your project needs.

- Prioritize Orders: Consider prioritizing orders or opting for expedited services if available for time-sensitive projects.

To avoid issues with turnaround times, maintain open communication with your printing company throughout the project. Consistent follow-ups and status checks help keep everything on track and prevent last-minute rushes.

Planning and proactive communication are the keys to avoiding problems related to turnaround times. By setting clear expectations and allowing for flexibility, you can ensure your wholesale screen printing project is completed on time and to your satisfaction.

Key Takeaway

Avoiding common mistakes when ordering wholesale screen printing is essential for achieving high-quality results and ensuring a smooth process. Understanding how to screen print correctly prevents errors that could impact your final product. Select suitable materials, review proofs thoroughly, and maintain clear communication with your printing partner to achieve the best possible outcome for your business needs.

Consider also the benefits of contract screen printing and screen printing fulfillment services when planning for wholesale screen printing. These options provide flexibility and scalability, allowing you to handle large orders efficiently. Proper planning and understanding the intricacies of the screen printing process will save time and resources, ultimately delivering superior results for your projects.

Ready to take your wholesale screen printing to the next level? At Scalable Press, we will guide you through the entire process, ensuring your projects meet the highest standards. Explore our product catalog to find the perfect solutions for your business.