Businesses needing promotional products must understand DTG vs screen printing to make informed decisions. This knowledge helps you choose the suitable printing method for custom apparel. DTG and screen printing offer unique advantages depending on your project’s requirements, from small to bulk orders and intricate details to vibrant colors.

Scalable Press offers both printing methods through our extensive print vendor network, allowing you to select the optimal solution for your promotional needs. Our modern software interfaces streamline the entire printing process with a single dashboard to manage all your orders efficiently. We provide competitive pricing and no minimum orders, making our services accessible and cost-effective for businesses of all sizes.

Drawing from our extensive experience, we’ve put together this guide exploring DTG vs screen printing. We’ll delve into how DTG printing and screen printing work and compare their key aspects. By the end of this blog, you’ll discover their core differences and determine the best option for your needs, whether digital printing or traditional methods like mesh screen printing.

Let’s get started!

What Is DTG Printing?

Direct-to-Garment (DTG) printing is a process where a DTG printer directly applies ink to textiles using inkjet technology. This method stands out for its ability to produce intricate designs and photorealistic images on garments. Unlike traditional screen print methods, DTG allows for more vibrant and detailed designs with its high-resolution color printing capabilities.

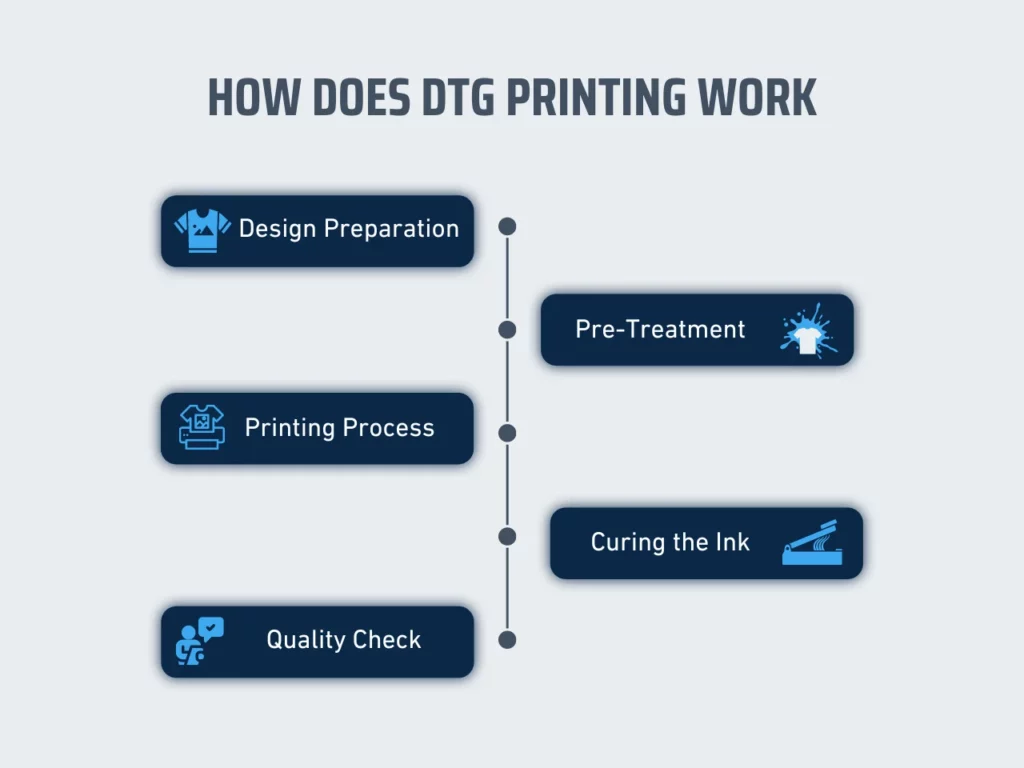

How Does DTG Printing Work?

DTG printing offers a modern method for producing high-quality prints on fabric. Here is how this printing method works:

- Design Preparation: The process begins with preparing the design on a computer. The design gets optimized for DTG printers, ensuring that intricate designs and photorealistic images are rendered well onto the garment. This step involves adjusting the colors and layout to match the capabilities of the inkjet printers.

- Pre-Treatment: The garment undergoes a pre-treatment process to ensure the DTG inks adhere correctly. This step involves spraying a special solution on the fabric, which helps the ink bond with the material. Pre-treatment is especially crucial for dark garments to keep the colors vibrant and durable.

- Printing Process: The garment is then loaded into the DTG machine. The inkjet technology in DTG printers applies the ink directly onto the fabric. This method allows for a wide range of colors and supports complex designs. The DTG printer uses a series of nozzles to spray the ink precisely, creating a high-quality print with fine details and sharp lines.

- Curing the Ink: After printing, the garment undergoes a curing process. This step involves using a heat press to dry and set the ink. Curing ensures the finished product has durable prints that can withstand multiple washes. Proper curing is essential to maintaining the quality and longevity of the DTG print.

- Quality Check: The final step involves a thorough quality check. The printed garment is inspected for color accuracy, detail, and print quality. This step ensures that the finished product meets the high standards of the client’s brand. Any defects or issues should be addressed before the garment is shipped to the customer.

Choosing the right printing method depends on your business model and specific needs. DTG printing produces high-quality, intricate designs and photorealistic images on garments with a fast turnaround for small orders. However, there may be better options for large orders due to its higher costs and slower production times.

What Is Screen Printing?

Screen printing is a popular technique for pushing ink through a stenciled mesh screen onto a substrate, like fabric or paper. Each color requires a separate screen, allowing for vibrant, multi-colored designs. It is widely used for creating custom apparel, posters, and promotional items. This method is favored for its versatility, durability, and ability to produce high-quality prints with sharp details. Screen printing is ideal for both small and large production runs.

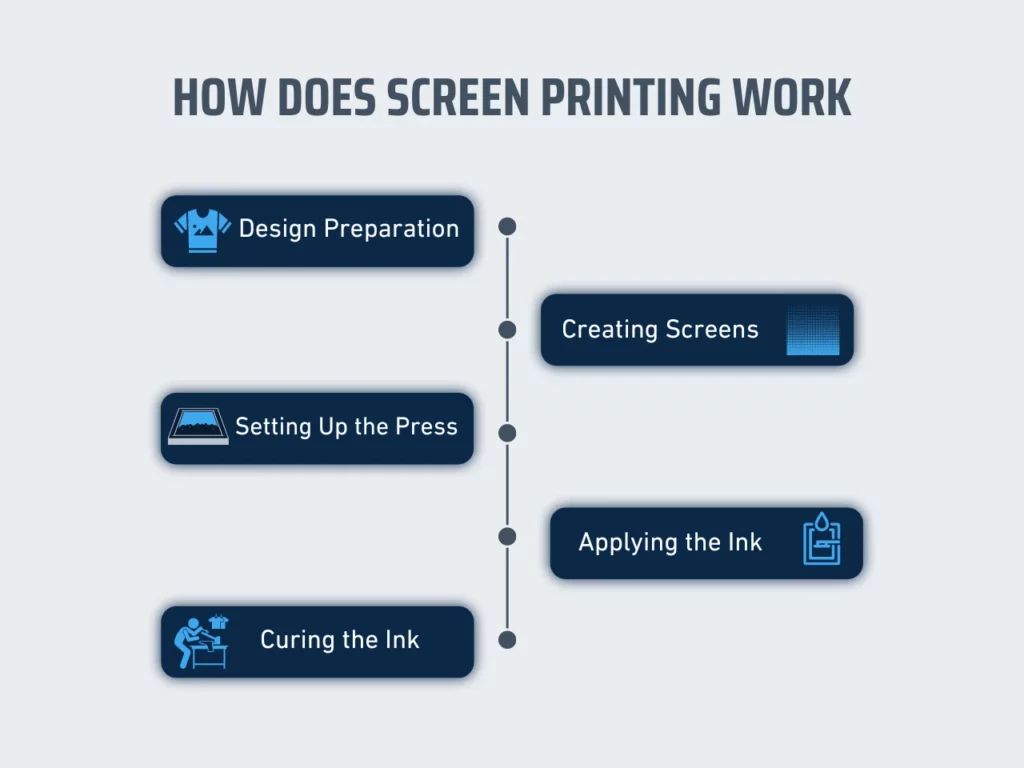

How Does Screen Printing Work?

Screen printing involves several steps that ensure high-quality prints, especially for large orders. Here is how screen printing works:

- Design Preparation: The process starts with creating the design on a computer. The design is then separated into individual colors, as each color requires a separate screen. This step ensures that intricate and complex designs are accurately reproduced.

- Creating Screens: Each color in the design needs its screen. A screen is a fine mesh stretched over a frame, coated with a light-sensitive emulsion. The design is then transferred onto the screen using a UV light exposure unit, hardening the emulsion where the design is not present. This creates a stencil for each color in the design.

- Setting Up the Press: The prepared screens are attached to the printing press. The garment is placed on the printing press, and the screens are aligned to ensure precise application of each color. Setting this process is crucial for maintaining the accuracy and quality of the finished product.

- Applying the Ink: Ink is applied to the screen and spread evenly across the surface using a squeegee, allowing it to pass through the mesh stencil onto the garment. This step is repeated for each color in the design, layering the colors to create the final image. Specialty inks like metallic or glitter can enhance the appeal of the garments.

- Curing the Ink: Once all colors have been applied, the garment will undergo a curing process. This involves using a conveyor dryer to set the ink. Proper curing ensures the print remains durable and vibrant after multiple washes, maintaining its quality over time.

Screen printing remains a preferred method for producing high-quality prints with vibrant colors and durability. Despite being labor-intensive, the process ensures that each garment meets high-quality standards. However, its higher setup costs and limitations with complex designs may only suit some business models.

DTG vs. Screen Printing: Top 9 Core Differences

Understanding the differences between DTG vs screen printing is crucial for businesses seeking the appropriate method for their garment printing needs. Each technique offers unique benefits and limitations, making it essential to choose based on specific project requirements. This comparison highlights their core differences to help you make informed decisions.

1. Print Quality

DTG printing produces high-quality prints with fine details and vibrant colors, making it ideal for photorealistic images and intricate designs. On the other hand, screen printing delivers solid, vibrant colors but may struggle with extremely detailed or small elements. The ink in screen printing sits on top of the fabric, while DTG ink penetrates the fibers, resulting in different textures and finishes.

2. Cost-Effectiveness

When considering DTG vs screen printing, cost-effectiveness plays a significant role. DTG printing is more economical for smaller orders due to its minimal setup requirements. Each print has a consistent cost regardless of the order size. Conversely, screen printing becomes more cost-effective with large orders because the setup costs are spread across more units, reducing the cost per piece as the order size increases.

3. Setup Time

The setup time for DTG and screen printing varies considerably. DTG printing involves a straightforward process requiring digital file preparation and minimal equipment setup. This results in faster start times for printing projects. Screen printing, however, demands a more intensive process that includes creating separate screens for each color in the design. This setup process can be time-consuming, particularly for complex, multi-color designs.

4. Versatility in Materials

DTG and screen printing differ in their compatibility with various materials. DTG printing is perfect for cotton or cotton-blend fabrics. The prints are vivid and long-lasting. Screen printing allows more variety. It works on many materials like polyester, blends, and special fabrics. This makes screen printing a better choice for diverse garment printing needs.

5. Durability and Longevity

Screen printing produces highly durable prints that withstand extensive use and washing without fading or cracking. The thick layer of ink forms a sturdy coating on the fabric. In contrast, direct-to-garment (DTG) printing produces prints that are moderately durable but may not last as long, especially on dark garments where white ink is utilized. DTG prints can experience some quality degradation after multiple washes.

6. Design Complexity

For complex designs and detailed artwork, DTG printing often proves superior. It allows for many colors and gradients, producing detailed and vibrant prints without additional setup costs. Screen printing, though adequate for simpler designs, faces limitations when handling intricate designs and multiple colors due to the need for separate screens for each color, increasing both setup time and costs.

7. Order Size Flexibility

Order size flexibility differs significantly between DTG vs screen printing. DTG printing efficiently handles smaller orders, making it suitable for custom orders, prototypes, or limited runs. Screen printing is more advantageous for large orders, as it becomes more cost-effective with higher quantities. Businesses should consider their typical order sizes when choosing between these two methods.

8. Production Speed

The speed of production varies between DTG and screen printing. Due to its minimal setup requirements, DTG printing offers faster turnaround times for small to medium orders. Screen printing can achieve high production speeds for large orders once the setup is complete, making it suitable for bulk printing. However, the initial setup can slow down the process for smaller runs.

9. Customization Capabilities

Customization capabilities differ between DTG vs screen printing. DTG printing excels in personalized and on-demand printing, allowing for easy adjustments to designs and colors without significant additional costs. Screen printing is less flexible in this regard, as changing designs requires creating new screens, making it less suitable for frequent changes or personalized prints. This makes DTG printing a better option for businesses offering custom or one-off designs.

DTG vs Screen Printing: Which One Is The Best Choice?

Choosing between DTG and screen printing depends on your specific needs. Each method offers unique advantages and fits different business models. Understanding these considerations ensures you select the correct method for your business needs and client expectations.

DTG Is Best For:

- Small Orders and Customization: DTG printing excels in handling smaller orders. It allows businesses to produce custom designs without requiring large quantities. This flexibility makes DTG ideal for online stores and small businesses offering personalized products.

- Intricate and Detailed Designs: DTG printing uses inkjet technology to produce highly precise, detailed designs. Businesses can print photorealistic images and fine lines on garments, making DTG the preferred choice for projects requiring high levels of detail and a wide range of colors.

- Quick Turnaround Times: Another significant advantage of DTG printing is the production speed. Without the need for extensive setup, businesses can fulfill orders quickly. This efficiency makes DTG suitable for print-on-demand services where fast delivery is crucial.

Screen Printing Is Best For:

- Large Orders: Unlike DTG, screen printing becomes more cost-effective with large orders. The setup costs are spread over a large quantity, reducing the overall price per unit. This makes screen printing the best choice for bulk orders, such as company uniforms or promotional products.

- Durability and Longevity: Screen printing uses thicker layers of ink, resulting in more durable prints. These prints withstand multiple washes, making them ideal for items that require long-lasting quality. Businesses looking for durable finished products will find screen printing advantageous.

- Versatility in Materials: Screen printing works well on various materials, including cotton, polyester, and blends. This versatility allows businesses to print on various products, from t-shirts to bags. The ability to use specialty inks, such as metallic and glitter, further enhances the appeal of screen printing for diverse applications.

Key Takeaway

Choosing the right printing method depends on your business needs. DTG vs screen printing offers distinct advantages. DTG printing excels with detailed and colorful designs, which is ideal for small batches. In contrast, screen printing proves more cost-effective for large orders with simpler designs. Understanding these differences helps businesses make informed decisions.

When comparing DTG and screen printing, consider cost, order size, and design complexity. For instance, DTG printing suits businesses needing vibrant, intricate designs on a small scale. Screen printing works best for businesses needing bulk orders with basic designs. Additionally, each method’s long-term durability and environmental impact should be considered.

Are you still deciding between DTG vs screen printing? Scalable Press provides expert guidance and a wide range of printing services. From cotton t-shirts and zip hoodies to accessories like phone cases and mugs, we have the perfect canvas to elevate your brand. Explore our product catalog to learn more and find the best fit for your promotional products.