Screen printing remains a popular method for creating promotional products, offering a versatile solution for businesses across industries. Its ability to produce vibrant, durable designs makes it ideal for creating custom apparel, signage, and other promotional items. However, businesses must assess whether in-house or contract screen printing best meets their project needs. Factors such as project scale, budget, and turnaround time significantly influence this decision.

At Scalable Press, we simplify the printing process for businesses through our extensive print vendor network. Our unified dashboard allows clients to manage their orders and coordinate with multiple print shops seamlessly. We offer competitive pricing for screen printing contract services while maintaining high quality. Whether you need screen printing, hybrid printing, or embroidery, we cater to the diverse needs of businesses.

Leveraging our expertise in the custom apparel industry, we’ve crafted this guide to explore the pros and cons of in-house and contract screen printing. We will explore the printing process of both options, contract pricing, and quality considerations to help you gain insights into which option best suits your specific needs.

Let’s get started!

In-House vs. Contract Screen Printing: Which Option Fits Your Project Needs?

Both in-house and contract screen printing offer distinct benefits that significantly impact quality, cost, and turnaround time. Understanding their advantages and drawbacks helps you make an informed decision tailored to your specific needs and goals. Let’s explore their differences to find the best fit for your project.

What is In-House Screen Printing?

In-house screen printing is a method where businesses oversee the entire screen printing process within their facilities. This involves using their own screen printer and other necessary equipment. Companies that opt for in-house screen printing handle everything from creating screens to printing on garments. This approach allows businesses to control every aspect of the printing process, ensuring that the final products meet their exact specifications and quality standards.

The primary benefits of in-house screen printing include complete oversight of the production process, which ensures quality printing and fast turnaround times. For businesses with frequent or large printing orders, this strategy can save them money, respond to client needs, and make adjustments as required. More than that, it eliminates the need to depend on third-party vendors when trying out different printing techniques like discharge and direct printing.

Use Cases of In-House Screen Printing

In-house screen printing offers unique advantages in specific scenarios:

- Custom Orders: Businesses handling custom orders benefit from in-house screen printing for its flexibility and ability to make quick adjustments to designs, ensuring customer satisfaction.

- Small to Medium Batches: For small to medium batch orders, in-house screen printing can be more efficient. The process minimizes delays associated with shipping artwork and garments to external printers. A screen print shop can manage these orders seamlessly.

- Brand Control: Companies with stringent brand guidelines benefit from the control in-house screen printing offers. This ensures consistency in color (using Pantone inks), logo placement, and overall design to maintain brand integrity.

- Specialized Techniques: In-house printing allows businesses to use specialized techniques like discharge ink and process printing, which is crucial to produce unique, high-quality prints that meet specific client needs.

- Rapid Prototyping: For businesses needing rapid prototyping, in-house screen printing provides the speed and control necessary to produce design samples quickly. This is essential for meeting tight deadlines and making fast adjustments.

Businesses that have particular printing needs can benefit greatly from in-house screen printing. It ensures quality control, fast turnaround times, and the ability to use specialized techniques. By managing the entire process in-house, companies can better meet their clients’ demands and maintain high standards in their printed products.

Pros and Cons of In-House Screen Printing

In-house screen printing offers unique benefits but also comes with challenges. Understanding these aspects can help businesses decide if managing screen printing internally is the right choice.

Pros of In-House Screen Printing

In-house screen printing provides several advantages that can be beneficial for certain businesses.

- Complete Control Over Production: Managing screen printing in-house allows businesses to fully control the production process, ensuring timeliness and quality standards are met.

- Flexibility in Customization: In-house printing allows quick adjustments and customizations, catering to specific client needs or last-minute changes.

- Cost Savings for Repetitive Orders: For businesses with ongoing or repetitive orders, in-house screen printing can reduce costs, especially when equipment and materials are already in place.

- Brand Consistency: Handling screen printing internally helps maintain brand consistency, as businesses can directly oversee color matching and design quality.

- Quick Turnaround Times: In-house screen printing often results in faster turnaround times, as businesses can prioritize their projects without waiting on external vendors.

Cons of In-House Screen Printing

Despite its benefits, in-house screen printing also presents several challenges that businesses should consider.

- High Initial Investment: Setting up an in-house screen printing operation requires significant upfront costs, including purchasing equipment and hiring skilled staff.

- Limited Capacity: In-house printing operations may need help to handle large or complex orders, limiting a business’s ability to scale.

- Ongoing Maintenance and Upkeep: Equipment maintenance and regular upkeep can be costly and time-consuming, potentially disrupting production schedules.

- Risk of Downtime: Equipment failures or staff shortages can lead to downtime, which can affect production timelines and client satisfaction.

- Space Requirements: Setting up an in-house screen printing requires dedicated space, which may only be feasible for some businesses.

What is Contract Screen Printing?

Contract screen printing is a process where businesses outsource their printing needs to a specialized contract printer. This method involves sending ready artwork and garments to an external screen print shop that handles the actual printing. Companies choose screen printing outsourcing to leverage the expertise and equipment of professionals, ensuring high-quality printing without investing in their machinery.

The benefits of screen printing contract services include access to advanced printing techniques like discharge printing and direct printing. Businesses can also take advantage of fast turnaround times, especially for large orders. Contract printing reduces the need for in-house equipment and staff, making it a cost-effective option for many companies.

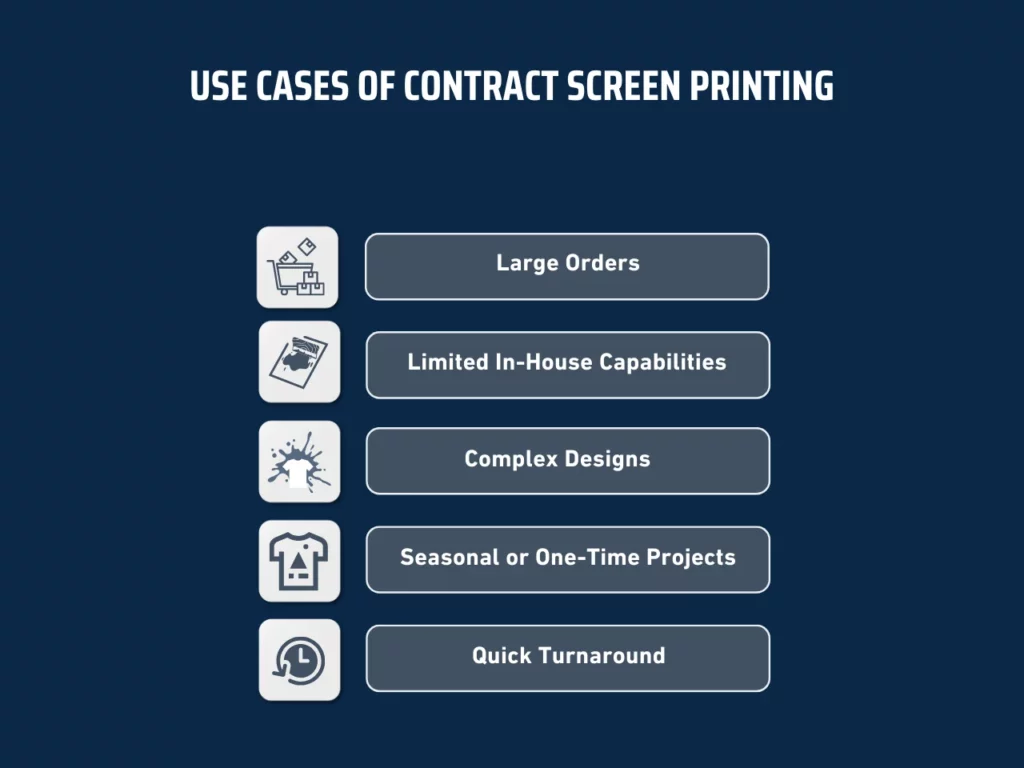

Use Cases of Contract Screen Printing

Contract screen printing is ideal for various business needs:

- Large Orders: Perfect for custom designs on t-shirts, hoodies, and other garments, allowing businesses to produce large quantities at a lower cost per unit.

- Limited In-House Capabilities: Companies without in-house screen printing capabilities can rely on contract screen printers. This allows them to offer screen printing services without investing in equipment.

- Complex Designs: Contract printers provide the expertise and equipment for detailed or multi-color designs. They offer process printing and discharge ink techniques, which require specialized knowledge.

- Seasonal or One-Time Projects: Businesses with seasonal or one-time projects benefit from outsourcing to a contract printer. This approach avoids the costs of setting up an in-house printing operation for short-term needs.

- Quick Turnaround: Contract screen printing is ideal when a fast turnaround time is crucial. Contract printers have the capacity and resources to meet tight deadlines and ensure timely delivery.

Businesses needing high-quality prints without managing the process internally can find immense value in contract screen printing. It is especially beneficial for large orders, complex designs, and projects requiring quick turnaround times.

Pros and Cons of Contract Screen Printing

Understanding the benefits and drawbacks of contract screen printing is essential for making an informed decision. Screen printing vendor services offer various advantages but have some limitations. Here’s a clear overview of the key pros and cons:

Pros of Contract Screen Printing

Contract screen printing provides several benefits, making it an attractive option for many businesses.

- Access to Advanced Equipment: Working with contract screen printers gives businesses access to state-of-the-art printing technology without purchasing expensive equipment.

- Scalability: Screen printing vendor services allow businesses to quickly scale up production for large orders, ensuring they meet high-volume demands.

- Expertise and Consistency: Professional screen printers bring expertise to the process, ensuring consistent product quality.

- Cost-Effectiveness for Bulk Orders: Contract screen printing is often more cost-effective for large orders, reducing per-unit costs and enhancing profit margins.

- Focus on Core Activities: Outsourcing screen printing frees up internal resources, allowing businesses to focus on their core activities.

Cons of Contract Screen Printing

Despite its advantages, screen printing vendor services have potential downsides that businesses should consider.

- Less Control Over Production: Outsourcing screen printing can reduce control over production, affecting timelines and quality.

- Dependency on External Vendors: Relying on third-party vendors for screen printing may introduce risks if the vendor faces delays or quality issues.

- Potential for Higher Costs on Small Orders: Contract screen printing might be less cost-effective for small orders, leading to higher costs per unit.

- Communication Challenges: Working with external vendors may lead to communication issues, resulting in misunderstandings or errors in the final product.

- Longer Lead Times: Contract screen printing often involves longer lead times, which may not suit businesses with tight deadlines.

Considerations When Choosing Between Contract and In-House Screen Printing

Businesses must carefully evaluate their unique needs and circumstances when deciding between contract and in-house screen printing. The choice impacts not only the cost but also the quality, scalability, and overall efficiency of the printing process. Here are five critical considerations to help you make an informed decision:

1. Project Scale and Complexity

Your project’s size and complexity should guide your decision. In-house printing works well for smaller, straightforward projects where customization and control are crucial. However, contract screen printing may be more suitable for large-scale or highly detailed orders. Outsourcing allows access to advanced technology and expertise, ensuring high-quality results.

2. Budget Constraints

Budget plays a significant role in choosing the right screen printing method. In-house printing requires an initial investment in equipment, materials, and skilled labor. While it may save costs for recurring projects, it can be expensive to maintain. On the other hand, screen printing contract services offer a cost-effective solution for large orders, as vendors often provide competitive pricing due to economies of scale.

3. Quality and Consistency Requirements

Quality control is essential for maintaining brand standards. In-house printing provides greater control over the production process, allowing businesses to ensure consistency in every print. However, contract screen printing vendors often specialize in this field, offering consistent quality across large batches. Choosing the proper method depends on your quality expectations and the importance of brand consistency.

4. Time Sensitivity

Turnaround time is a crucial factor, especially for time-sensitive projects. In-house printing can offer faster response times since everything is managed internally. However, screen printing contract services may be better if your business takes time to handle large orders. Vendors typically have the resources to manage tight deadlines without compromising quality.

5. Long-Term vs. Short-Term Needs

Consider whether your screen printing needs are long-term or project-based. Investing in in-house printing may provide more flexibility and control for ongoing needs. However, if your business requires screen printing services only occasionally or for specific campaigns, contract screen printing can be a more practical and cost-effective solution.

Key Takeaway

Choosing the right screen printing method depends on your project’s specific needs. Whether you require in-house or contract screen printing, aligning your choice with your project’s scale, complexity, and timelines is essential. Carefully considering these factors ensures that your final product meets your expectations without unnecessary costs or delays.

Before deciding, take time to assess your business needs. Consider whether your project requires digitizing a drawing or involves complex designs that might benefit from contract screen printing. If your project aligns with Print-on-Demand services, comparing options like Printful vs. Printify could also be beneficial. These considerations will ensure that your final decision supports short-term project goals and long-term business growth.

Still deciding which method suits your business? Learn more about DTG vs. screen printing and determine which works best for your next project. At Scalable Press, we help businesses navigate these choices with our extensive network of contract screen printing vendors. Explore our product catalog featuring 4,000+ products to find the perfect fit for your screen printing needs.